Automatic Robot Laser Welder

Home > 6 Axis Robotic Laser Welding Machine

6 Axis Robotic Laser Welding Machine

Welding Robot:

FANUC, Yaskawa, ABB, CRP

Application:

Iron, stainless steel, galvanized and aluminum alloy, etc.

Industry:

Automobile, aerospace, metal processing manufacturing, etc.

Axis Qty:

6 Axis, 7 Axis, 8 Axis, 9 Axis (Option)

Customized:

One-stop supply of welding, robots and peripheral equipment

Product Presentation

Machine Description

The 6 Axis Robotic Laser Welding Machine can complete the connection at any position in space.

The perfect combination of the robot arm and the fiber laser welding machine meets various automated production needs. It is suitable for the automotive industry, aerospace, metal processing and manufacturing, household appliances and kitchen supplies, medical equipment, electronics industry, rail transportation, shipbuilding and other industries.

We provide automation solutions for different industries.

With the help of technology-specific M.RISE application software, M.RISE provides tailor-made solutions for robot-based laser applications. We provide components for robot and laser applications, from robots to pre-configured welding cells to various robot peripherals (single/double/triple-station worktables, positioners, fixtures, etc.).

Benifits of Laser Welding Robots

1. Good welding effect

Efficient and precise laser welding, for workpieces with wider welds, the robot can achieve efficient and precise laser welding, with better weld quality, smoother and more beautiful surface, and improve the quality and appearance of the product. The use of advanced swing welding head has expanded the scope of application of laser welding and can handle larger workpieces.

2. Even more flexible than human hands

The robot has excellent freedom of movement and extremely high repeatability. The slender wrist and arm can not only enter narrow spaces, but also the six-axis design can weld in any space without being restricted by a specific plane. It can manipulate large laser heads and has excellent performance – circular, curved and linear paths. The robot has high repeatability to ensure welding accuracy and consistency.

3. Uninterrupted work

The robot arm can work 24 hours a day and can rotate left and right for double-station work, which improves work efficiency, increases safety and saves labor costs.

Machine Details

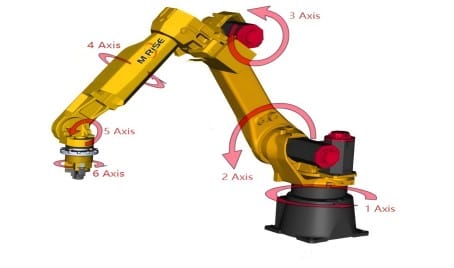

Robot Structural

◆ The 6-axis robot consists of six joints: rotation (1 axis), lower arm (2 axis), upper arm (3 axis), wrist rotation (4 axis), wrist swing (5 axis) and wrist rotation (6 axis);

◆ The synthesis of 6 joints realizes 6 degrees of freedom movement at the end, slim design, and high flexibility

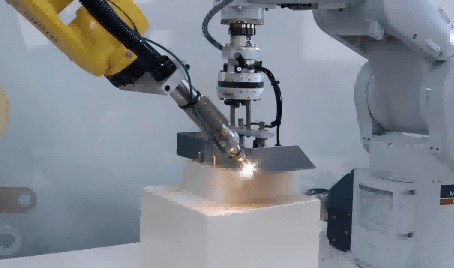

High Precision Laser Welding

◆ In robotic applications, high-energy laser beams are usually guided to the processing location via flexible optical fibers.

Here, the laser power is focused onto a small focal spot with the aid of optics. The resulting high energy density melts the workpiece and welds the component.

◆ There is minimal deformation, good weld seams, and no post-weld grinding is required.

◆ The parameters can be adjusted depending on the material and process.

Robot Controller

◆ With the software developed by mrise, laser welding and laser cutting applications can be easily programmed and quickly realized;

◆ Equipped with easy-to-use video tutorials, beginners with no welding experience can also operate easily;

◆ If you have needs, we can go to the customer site to install and debug for you, and provide on-site training.

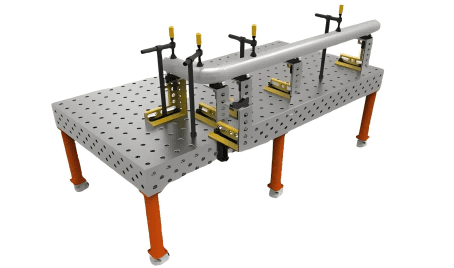

Customized Worktable and Jigs

◆ The fixture can accurately position the workpiece to ensure that the relative position accuracy of the weld is generally within 1mm, meeting the requirements of automated welding for repeatability and stability;

◆ It can be customized according to the shape and structure of the welded part to meet the production needs of different products;

◆ The fixture supports rapid loading and unloading and repeated positioning of the workpiece to meet the needs of mass production;

◆ The electromagnetic fixtures, pneumatic fixtures or mechanical fixtures are used to quickly fix the workpiece, reduce clamping time and improve production efficiency.

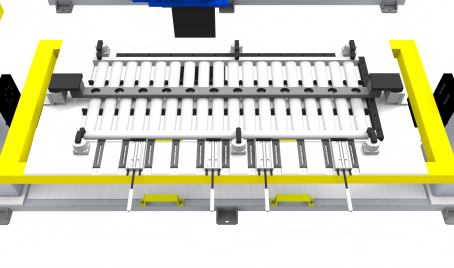

Dual-station robot welding

◆ Two robots welding at the same time on dual-station, double the work efficiency

Optional positioners

◆ The different types of positioners match depends on different workpieces.

◆ At the same time, more axes can be added to meet the welding needs of different workstations.

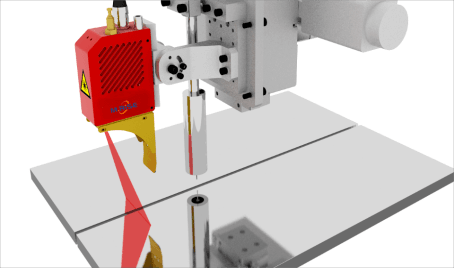

Weld Seam Tracking Function

◆ Before or during welding, the laser vision weld tracking system quickly scans the workpiece joint, obtains the real space coordinate data of the weld, calculates the weld deviation data through the system;

◆ Transmits signals to the PLC or motion controller, drives the actuator mechanism to adjust the welding trajectory according to the actual workpiece position, and realizes the automation of the welding process.

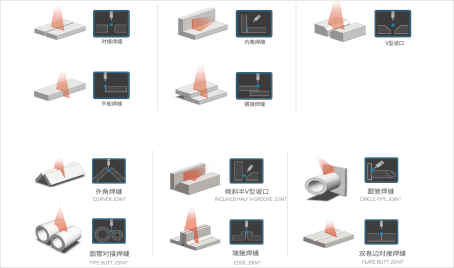

Inspection of Various Weld Seam Types

◆ Various types of welds can be inspected.

For example, Butt welds, Lap welds, and Fillet welds.;

◆ Non-standard weld inspections can also be customized: Coner joint, Include half V-Groop joint, Pipe butt joint, Edge joint ect.

Machine Parameter

No.

Item

Parameter

1

Machine Model

MR-2000RW/3000RW/6000RW

2

Laser Power

2kw/3kw/6kw Option

3

Robot Brand

FANUC, Yaskawa, ABB, CRP

4

Maximum robot load

12kg, 18kg, 25kg

5

Robot Arm Show

1.45m, 1.5m, 1.6m, 1.8m, 2m(Depends on different brand and models)

6

Welding speed

0-120mm/s

7

Galvo scan speed

≤8000mm/s

GET A QUOTE

Talk to Expert and Get Tailored Welding Solution Free

Help you to weld smarter, faster, and better

Warranty&Service

1. 3-Year Warranty for the Entire Machine;

2-Year Warranty for Laser source, Air compressor, Stabilizer;

If any parts are damaged during the warranty period, we will repair or replace them with new ones free of charge.

2. Whole lifetime and 24 hours online service.

Free technical support to guide the customer by WhatsApp, Wechat, Skype, Viber, E-mail for installation, maintenance, repair and software update.

3. The machine has undergone strict quality inspection and debugging before shipment.

And we already gained CE, FDA, ISO certificates, ect. So that we can export to any countries and areas in the world.

4. We have manual instruction, Videosand CD/U disk for software installation,operation and machine’s using and maintenance.

5. We provide the consumable parts at an agency price.

Related Machines

Three-chuck Tube Laser Cutting Machine

Diameter: ∅120mm-∅550mm | Tube Length:6-12m

OPEN TYPE Metal Sheet Fiber Laser Cutting Machine

Work Area: 3000*1500mm | Laser Power: 3kw-30kw