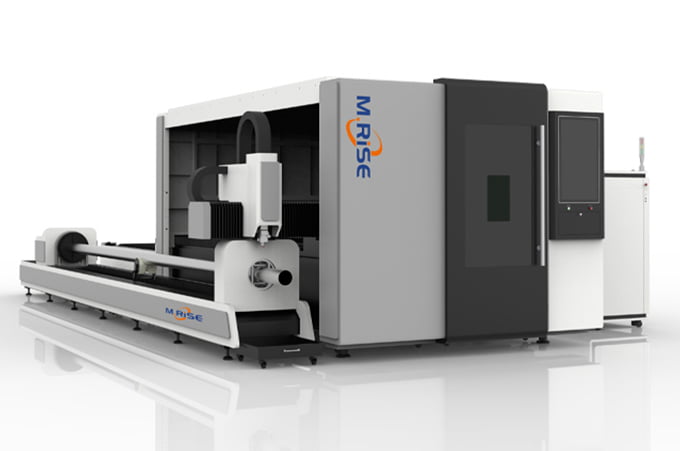

Tube Metal Fiber Laser Cutting Machines

Home > Fiber Laser Tube Cutting Machine

- Tube Metal Fiber Laser Cutting Machines

Three-chuck Tube Laser Cutting Machine

Diameter: ∅120mm-∅550mm| Tube Length:6-12m

Entry-Level Tube Metal Laser Cutting Machine

Diameter: ∅120mm-∅220mm| Tube Length:6-8m

Semi Loading Tube Laser Cutting Machine

Diameter: ∅120mm-∅220mm| Tube Length:6-8m

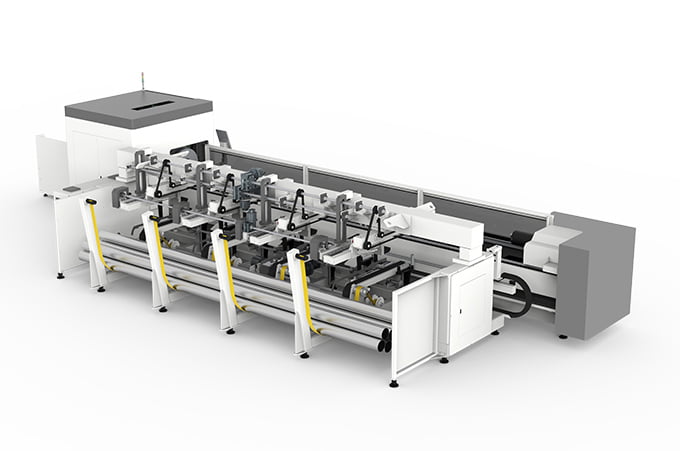

Fully Automatic Tube Laser Cutting Machine

Diameter: ∅120mm-∅450mm| Tube Length:6-12m

Robot Tube Laser Cutting Machine

3D Cut | 6 Axis - 8 Axis

Ultra Size Metal Pipe Laser Cutting Machine

Diameter: ∅350mm-∅650mm| Tube Length:6-12m

Affordable Sheet and Tube Laser Cutting Machine

Sheets up to: 8000*2500mm | Tubes up to: ∅220mm

Sheet and Tube Fiber Laser Cutting Machine

Sheets up to: 8000*2500mm | Tubes up to: ∅220mm

- Machine Video

The Laser Cutting Machine could cut most kinds of tube metal materials as follows:

- Stainless Steel Tube

- Mild Steel Tube

- Aluminum Tube

GET A QUOTE

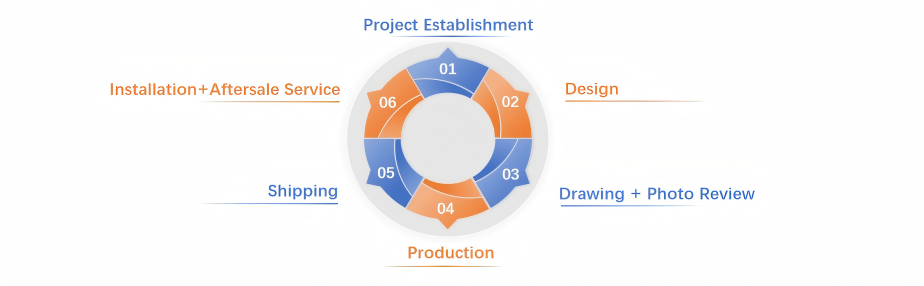

Talk to Expert and Get Tailored Cutting Solution Free

Help you to cut smarter, faster, and better

Why Choose M.RISE

Quality Certification

Certified by CE, ISO 9001, FDA, and RoHS, our machines meet the highest standards of quality and safety

OEM/ODM and Customized Solution

We provide customized production line solutions for various industries, backed by an R&D team with over 10 years of experience.

GOLD Warranty

3-Year Warranty,

Free lifetime based TECH support

24/7 Customer Service

Our multilingual team of professional engineers responds within 1 hour and provides both online and on-site paid services for machines from other brands

WHAT OUR CUSTOMERS SAY

What materials can a fiber laser cutting machine cut?

Fiber laser cutting machines can cut a wide range of metals, including stainless steel, carbon steel, aluminum, brass, copper, titanium, and alloy steels. They are especially effective for reflective materials like brass and copper, which are challenging for other laser types.

How thick can a fiber laser cut?

Cutting thickness depends on laser power.

For example: 1500w cuts up to 6mm stainless steel; 3000w cuts up to 10-12mm stainless steel; 6000w cuts up to 25-30mm mild steel or 16-18mm stainless steel.

Higher power(e.g., 12kw, 20kw, 40kw) can handle even thicker materials.

What gas is used for fiber laser cutting?

Common gases include:

Nitrogen: for clean cuts on stainless/aluminum-Some systems integrate nitrogen generators to reduce long-term costs.

Oxygen: for carbon steel, helps oxidize the material

Air: cost-saving option for thin sheets, with lower quality

What maintenance does a fiber laser cutter require?

Routine tasks include:

Cleaning protective lens weekly; Checking laser head alignment; Replacing filters (air/dust); Ensuring dust removal systems are functional; Professional service checks are advised every 6–12 months.