Foam & Insulation Industry Cutting Application

Home > CNC Vibrating Knife Cutting for the Foam & Insulation Industry

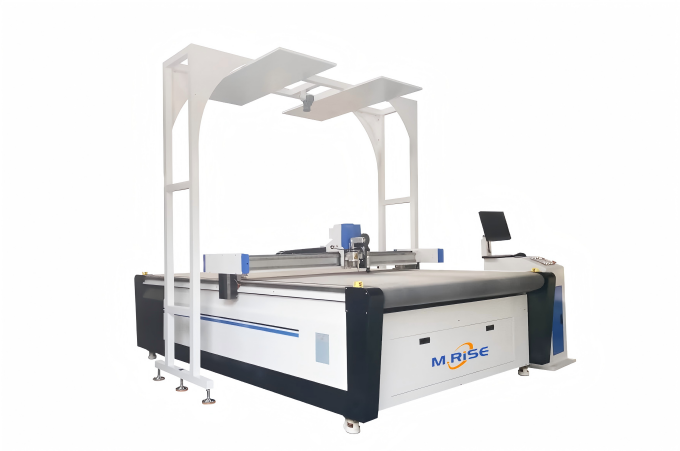

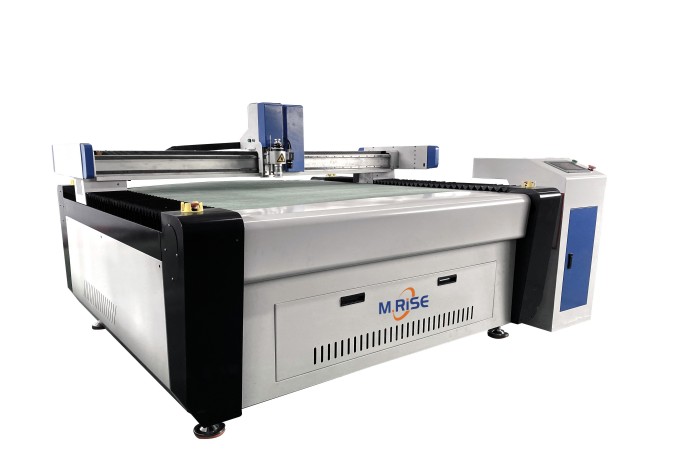

Knife Cutting Insulation Machine | CNC Vibrating

Oscillating Knife Cutting Video

Introduction

Foam and insulation materials are widely used across industries—from automotive and aerospace to construction, packaging, and home appliances. These materials often come in large sheets, rolls, or multi-layer composites, making traditional manual or die-cutting methods inefficient, inconsistent, and wasteful. This is where a CNC Knife Cutting Insulation Machine (also known as a CNC Vibrating Knife Cutter) provides the perfect solution.

Our CNC Vibrating Knife Cutting Machine provides a clean, accurate, and fully automated solution for cutting various types of foam and insulation with no deformation, no dust, and no tool wear. It is particularly suited for soft to semi-rigid materials such as EPE, EVA, XPE, PU foam, PE foam, acoustic insulation, thermal insulation, and rubber-based products.

With smart digital control and high-speed oscillating blade technology, manufacturers can achieve complex contours, internal cuts, and precise shapes in a single pass—without the need for molds or heat.

Cutting Materials

- Soundproof & Acoustic Materials: sound insulation cotton, polyester fiber boards, acoustic panels, fabric sound-absorbing panels.

- Thermal Insulation: glass wool, thermal insulation cotton, flame-retardant fabrics.

- Foam-Based Insulation: EPE, EVA, XPE, PU foam, PE foam, sponge, cushion foam.

- Adhesive & Composite Materials: adhesive sound insulation, rubber-based insulation, multilayer laminates.

Features

- Non-Contact Cold Cutting for Foam & Insulation

The vibrating blade operates without generating heat, preserving material integrity and ensuring clean, burr-free edges. - Supports Multi-Layer Cutting of Acoustic & Thermal Materials

Cuts up to several layers simultaneously, significantly boosting efficiency for high-volume production. - Versatile Tool Head System for Insulation Cutting Machine

Combine multiple tools—oscillating knife, drag knife, creasing wheel, punching—for tailored cutting solutions. - Compatible with Large Sheets and Rolls (Foam, Cotton, Fiberglass)

Handles oversized formats with vacuum or conveyor table options to streamline continuous cutting. - Auto Nesting & Material Saving

Built-in intelligent nesting software maximizes material usage, reducing cost per unit. - Dust-Free, Noise-Controlled Operation

Clean workshop environment, especially beneficial for acoustic or thermal insulation production.

Benefits

- No Die Needed: Reduce setup time and eliminate the cost of metal dies.

- Fast Turnaround: Switch from one design to another in minutes, ideal for custom orders or short production runs.

- Exceptional Cutting Accuracy: Precise cuts even on soft, thick, or elastic materials.

- Lower Scrap Rate: Accurate nesting and consistent cutting improve material yield.

- Safe & Energy Efficient: No risk of burns or deformation, and significantly lower energy consumption compared to laser cutting.

Compared with laser cutting or die-cutting, a Knife Cutting Insulation Machine ensures safe, dust-free, and highly efficient production for foam and insulation industries.

Applications

- Packaging foam inserts cut by CNC Knife Cutting Machine

- Automotive insulation & soundproof foam cutting

- Building thermal insulation panels cutting

- Furniture cushion & sponge foam cutting

- Acoustic insulation cutting machine for panels & mats

- Foam padding cutting for sports protection

- HVAC insulation cutting solutions

- Medical foam cutting with CNC vibrating knife

CNC Sound Insulation Cutting Machine

Our CNC Knife Cutting Insulation Machines are designed for manufacturers who demand precision, flexibility, and efficiency. Whether you’re producing large volumes of insulation panels or small customized foam parts, our systems can adapt to your production needs and help you scale your output—without compromising on quality.

From prototyping to full production, our machines ensure repeatable performance, reduced lead times, and significant cost savings.

Whether you call it a CNC Vibrating Knife Cutter, a Digital Flatbed Cutting Machine, or a Knife Cutting Insulation Machine, our technology helps you cut smarter, faster, and cleaner.

GET A QUOTE

Talk to Expert and Get Tailored Cutting Solution Free

Whether you’re exploring options or ready for a quote, our team is ready to support you with honest answers and fast service.Tell us what you need—just one minute to get started.