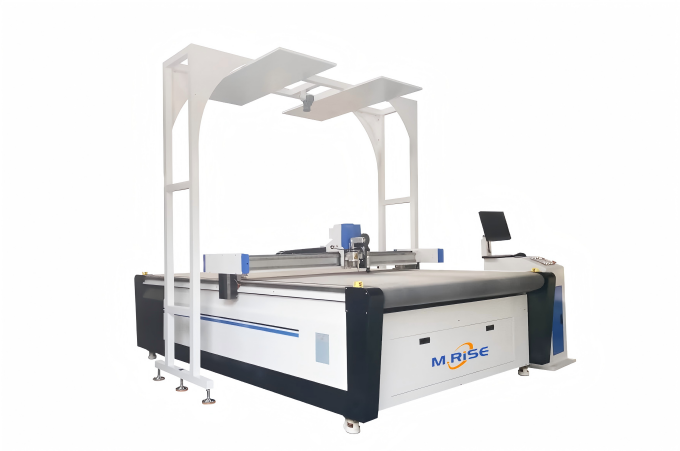

Acoustic Panel Cutting Machine

Home > CNC Sound Insulation Cutting Machine

CNC Sound Insulation Cutting Machine

Cutting Materials:

Sound Insulation Cotton, Flame Retardant Fabric, Polyester Fiber Sound-absorbing Board, Insulation Cotton, Sound-absorbing Panel, Adhesive Sound Insulation, Glass Wool, ect.

Supply Capacity:

300 Sets Available per Month

Delivery:

7 Days

Certificate:

CE Certified for Quality and Safety

Warranty:

3-Year Warranty + Lifetime Free Technical Support

Payment Term:

Online (PayPal, Alibaba Trade Assurance) / Offline (T/T, Credit or Debit Card)

Product Presentation

CNC Sound Insulation Cutting Machine Description

Intelligent Precision for Acoustic Material Cutting

When it comes to cutting delicate, fibrous, and high-performance acoustic materials, precision matters. The M.RISE CNC Acoustic Panel Cutting Machine is designed specifically for professionals in the sound insulation, thermal insulation, and acoustic panel manufacturing industries.

Powered by intelligent software and precision hardware, our system delivers high-efficiency, high-accuracy cutting across a wide range of materials, including fiberglass acoustic cotton, polyester fiberboard, PET felt, EVA foam, rock wool, and more — all without burrs, dust, or material damage.

- Why Choose M.RISE for Acoustic Panel Cutting?

One-Click Smart Cutting

Import design files with a single click and let the intelligent CAM software optimize cutting paths automatically. - No Mold, No Burrs, No Hassle

Enjoy clean, smooth edges with high repeatability — without costly molds or manual finishing. - Adaptive Tooling

Supports multiple knife types for bevel cutting, slotting, grooving, and special-shaped profiling across different acoustic materials.

Core Features & Technical Highlights

- Optimized Cutting Efficiency

Proprietary software compensates in real time and increases cutting speed by up to 30% compared to traditional machines. - Superior Accuracy

Built-in precision linear guides deliver cutting accuracy within ±0.1mm, ensuring consistency across large batch runs. - Material Flexibility

Suitable for cutting materials from 0.5mm to 50mm thick, including: Fiberglass sound insulation cotton, Polyester fiber acoustic panels, PET felt panels, Natural fiber acoustic boards, Rock wool & mineral wool insulation, EVA foam, composite cotton, and more - Energy-Efficient Design

Features a variable-frequency vacuum system that reduces power consumption by over 30% while maintaining strong material hold - Safe Operation

- Infrared sensors ensure operator safety during high-speed cutting

- Anti-static protection and soft-start motor control preserve machine integrity and prevent material loss

Application Scenarios

- Construction & Interior Soundproofing

Cutting custom panels for walls, ceilings, and insulation systems. - Recording Studios & Theaters

Creating customized sound-absorbing elements for acoustical treatments. - Insulation Product Manufacturing

High-volume batch cutting for thermal and acoustic cotton rolls, boards, and panels. - Custom Furniture & Panel Design

Precise shaping of soundproof layers in composite furniture or modular office dividers.

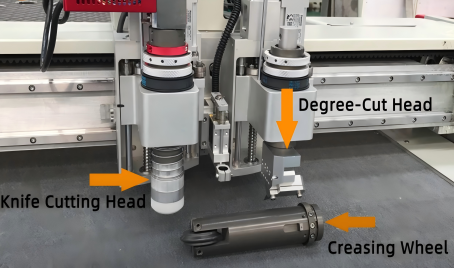

CNC Sound Insulation Cutting Machine Details

EOT+Degress Cut Head+Creasing Wheel

◆ The EOT for fast speed cutting.

◆ The Creasing Wheel is working for sound insulation creases.

◆ Degree-cut Head is adjustable groove angles (0°, 15°, 22.5°, 30°, 45°) for display structures

Option Punching Tool

◆ Punching tool is used for puching holes on any materials, such as gasket, leather, fabric, carpet, corrugated paper, offset paper, grey board, rubber, honeycomb board, PP, PE, and PVC)

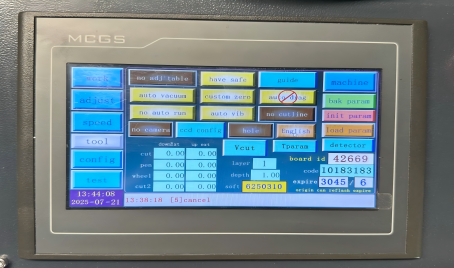

CNC Intelligent Control System

◆ Touch screen for easy operation

◆ Multi-language mode: English, Korean, Spanish, Portuguese, Turkish, etc.

Servo Motor and Driver

◆ Equipped with High precision servo motors and the exclusive MR-CUT intelligent control system, delivering smooth motion and pinpoint accuracy.

◆ The MAX cutting speed is 1600mm/s, 3-5 times than traditional cutting.

Aluminum Vacuum Adsorption Table

◆ The heavy-duty welding bed and aluminum vacuum adsorption table ensure stability during high-speed cutting.

◆ The adsorption platform can fix the material and ensure cutting accuracy.

Zoned Exhaust System

◆ The platform is divided into several areas for ventilation work to ensure that the adsorption platform works well during cutting.

High-power Exhaust Fan

◆ High-power fan supports partition adsorption function, with stronger adsorption force cutting accuracy.

High-density Felt Countertops

◆ The felt contains metal wire, suitable for automatic feeding table and durable very much

CNC Sound Insulation Cutting Machine Parameter

No.

Item

Parameter

1

Machine Model

MR-1625

2

Tube Cutting Size

1600*2500mm(63 x 98.4''), 1800*2500mm(70.9 x 98.4''), 2100*3000mm(82.7 x 118.1'')-Customized depends on your requirement

4

Cutting Speed

100-1600mm/s

5

Cutting Thickness

0.1-100mm (Adjustable based on materials and requirement)

6

Cutting Accuracy

±0.01 mm

7

Positioning Accuracy

±0.01 mm

8

Cutting Materials

Sound Insulation Cotton, Flame Retardant Fabric, Polyester Fiber Sound-absorbing Board, Insulation Cotton, Sound-absorbing Panel, Adhesive Sound Insulation, Glass Wool, ect.

9

Cutting Tools

Oscillating blade head, V-cut, Tangential Knife, Router, Kiss-cut, Creasing wheel, Milling head, Pneumatic Blade head, Marking pen, Punching, ect.

10

Application Pen Type

Common signing pen, Oil pen, Ball-point pen, Silver pen

11

Table Fixed Type

Vacuum worktable/Zoned adsorption platform

12

Rack and Linear Guide

Taiwan

13

Motor and Driver

Servo Type

14

Machine Base

Welded squre metal tube of heavy duty

15

Lubrication System

Automatic Lubrication

16

Control Software

Zhongrui with Touch LED Screen

17

Support Files Format

PLT, AI, CDR, HPG, HPGL, ect.

18

Option Parts

CCD Camera, Big Camera, Projector, Automatic deviation correction loading rack

GET A QUOTE

Talk to Expert and Get Tailored Cutting Solution Free

Help you to cut smarter, faster, and better

FAQs

- The machine is designed to cut a wide range of soundproofing materials including PU foam, rubber composite sheets, fiberglass insulation, acoustic panels, felt, and multilayer laminates with consistent precision.

- Thanks to advanced CNC motion control and optional oscillating blade systems, the machine delivers high cutting accuracy (±0.1 mm), even for intricate, curved, or multi-layer acoustic designs.

- Yes. It could cut some complex, multi-material sound insulation panels with consistent pressure control and automatic depth adjustment.

- Absolutely. The machine is built for industrial-scale operations with fast cutting speed, auto-feeding, nesting software, and material optimization—ideal for car interior, HVAC systems, or construction acoustic panels.

- Compared to manual or die-cutting, CNC cutting offers higher flexibility (no mold required), shorter production setup times, minimal waste, and clean, accurate edges without material distortion.

- Depending on the model, the machine typically supports up to 50mm thick insulation materials and 100mm foam.

- We provide free installation and training online.

- Our engineer will help to install the machine at your factory if necessary.

- Regular cleaning and lubrication are essential, but most machines offer user-friendly maintenance routines. Some models even have automated cleaning mechanisms.

- The ROI varies depending on factors like production volume, labor costs, and material savings. However, many businesses see a significant return on investment within a short period due to increased efficiency and reduced waste.

- All machines are relatively user-friendly and require minimal training. We offer training resources and support to ensure smooth operation.

- 1 year of whole machine;

- Free technicial support and software updating of lifetime;

- Repair parts and consumables that need to be replaced are provided to customers at dealer prices.