In the competitive world of modern manufacturing, businesses are under constant pressure to deliver high-quality products while reducing costs and increasing productivity. Whether you’re in textiles, automotive, packaging, or leather goods, the challenge of balancing these competing demands is something we all face. As an American customer, you might often struggle with costly, unreliable equipment that can’t keep up with your increasing production needs.

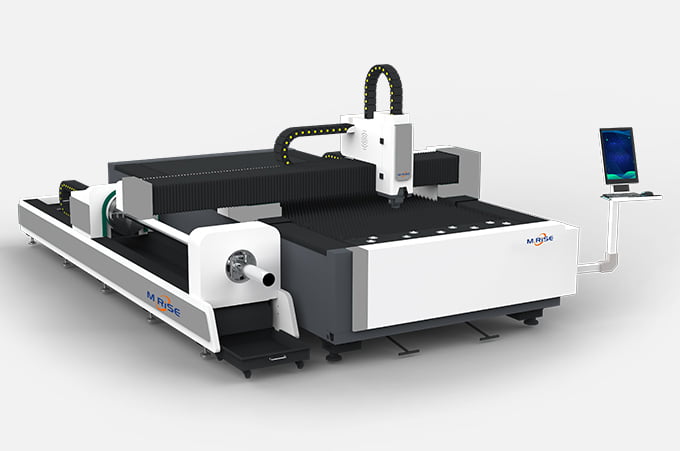

This is where M.RISE CNC Digital Knife Cutting Machine comes in. Manufactured in China using the latest technology, this machine is designed to tackle your most pressing production pain points head-on, delivering precision, efficiency, and cost savings.

Common Pain Points and How Our CNC Digital Knife Cutting Machine Solves Them

- Precision and Consistency Issues

For many businesses, achieving consistent quality in cutting is a major hurdle. Whether it’s uneven cuts, misalignment, or inaccuracies in intricate designs, these errors can lead to waste and rework.

Solution: Our CNC Digital Knife Cutting Machine utilizes advanced motion control systems to guarantee highly accurate cuts every time. Whether you’re cutting textiles, cardboard, leather, or foam, the machine’s high-precision knife ensures consistent results. This minimizes material waste and reduces the need for costly corrections.

- Production Downtime Due to Equipment Failures

Frequent machine breakdowns are a nightmare for manufacturers, especially when dealing with older or poorly built equipment. This results in lost time, missed deadlines, and unhappy customers.

Solution: The CNC Digital Knife Cutting Machine is engineered for durability and continuous operation, even in high-demand environments. Our machines are built with high-quality materials and have a low failure rate, ensuring that your production line stays running smoothly without constant interruptions.

- High Labor Costs and Skill Gaps

In many industries, the need for specialized labor is a growing concern. Skilled technicians can be hard to find, and labor costs are rising.

Solution: Our machine comes with an intuitive, user-friendly interface, reducing the need for specialized training. Operators can quickly learn how to operate the system, saving you on labor costs while increasing overall productivity. Additionally, automation reduces the reliance on manual labor, lowering the risk of human error and speeding up the production process.

- High Operational Costs Due to Inefficiency

Many businesses are grappling with high operational costs. Inefficient machines that waste material, require frequent maintenance, or run at low speeds are a major contributor.

Solution: The CNC Digital Knife Cutting Machine is designed for efficiency. With its high-speed cutting capabilities and minimal material waste, it helps you save on production costs. Additionally, the machine is energy-efficient, further lowering your overall operational expenses.

- Lack of Technical Support and Maintenance Services

After investing in high-end machinery, many customers find that after-sales support and maintenance services are lacking or difficult to access. This can lead to frustration and unplanned downtime.

Solution: As a manufacturer, we take pride in our excellent after-sales service. We offer comprehensive technical support, training, and easy access to spare parts, ensuring that your machine continues to operate at peak performance for years to come. Our customer support team is always ready to assist you, solving problems quickly and efficiently.

Real Results for Real Businesses

Our CNC Digital Knife Cutting Machine has been implemented across various industries with impressive results:

- Textile Industry: Companies have reduced fabric waste by 20% and increased production speed by 30%, leading to significant cost savings.

- Leather Goods: Leather manufacturers have achieved a 15% improvement in cutting precision, reducing defects and improving the overall quality of their products.

- Packaging: Companies in the packaging industry have reported 25% faster production times, resulting in higher throughput and customer satisfaction.

Why Choose Us?

When you invest in our CNC Digital Knife Cutting Machine, you’re not just getting a machine — you’re getting a comprehensive solution to your production challenges.

Our machines offer:

- Advanced Technology: Equipped with state-of-the-art features like high-precision motion control and automated cutting processes, our machines lead the industry in innovation.

- Long-Term Value: With lower operational costs, reduced maintenance needs, and longer service life, our machines are an investment that will pay off over time.

- Reliable Support: We stand by our products with unparalleled after-sales support, ensuring your business can run smoothly with minimal downtime.

Conclusion: A Smart Investment for Your Business

By choosing our machine, you’re not only investing in cutting-edge technology, but also ensuring long-term cost savings and a boost in productivity. With our commitment to excellent after-sales support, you can trust that your investment will continue to deliver value for years to come.

Take the next step in optimizing your production and contact us today. Let’s discuss how the CNC Digital Knife Cutting Machine can help you stay ahead of the competition.