Introduction

When operating a CNC oscillating knife cutting machine, one of the most overlooked yet critical components is the felt mat, also known as the felt conveyor belt. This simple-looking accessory plays a decisive role in ensuring cutting accuracy, material stability, and the lifespan of your cutting blade.

In this article, we will explore everything you need to know about vibrating knife felt mats — their structure, function, selection guide, and how to maintain them for optimal performance.

What Is a CNC Oscillating Knife Felt Mat?

A felt mat (or cutting felt belt) is a high-density, wear-resistant layer installed on the cutting table or conveyor of CNC oscillating knife cutters.

Its main function is to:

- Hold the cutting material in place through vacuum adsorption

- Protect the blade from damage during high-frequency vibration

- Provide a stable, smooth cutting surface

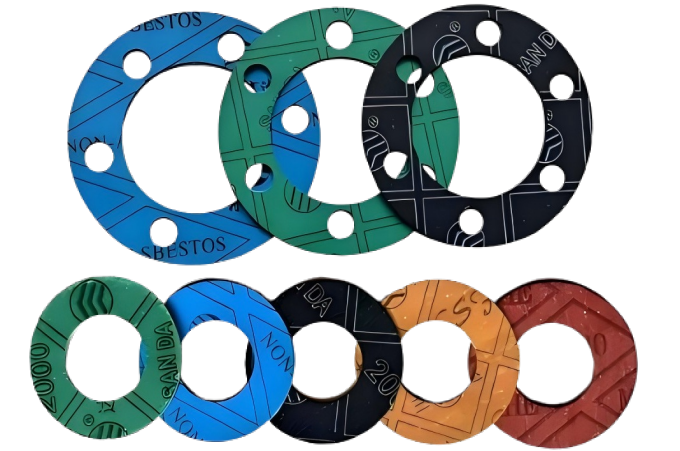

These felt mats are widely used in cutting fabrics, leather, sponge, cardboard, automotive interiors, composite materials, and advertising foam boards.

Structure and Types of Felt Conveyor Belts

There are generally two types of felt belts used in CNC digital cutting machines:

1. Single-Sided Felt Conveyor Belt

- One side is a felt layer, and the other side is PVC base belt.

- Lightweight and affordable.

- Suitable for basic flatbed cutting tables or environments where felt thickness is not critical.

2. Double-Sided Felt Conveyor Belt

- Both sides covered with felt for better grip and cushioning.

- Provides higher friction, noise reduction, and bidirectional conveyance.

- Ideal for auto-feeding cutting systems and continuous production lines.

Key Features of High-Quality Felt Mats

When choosing a CNC cutting felt mat, quality directly affects cutting precision and equipment lifespan.

Here’s what to look for:

- Cut-resistant surface – withstands repeated knife vibration without tearing

- High tensile strength – resists stretching and deformation

- No fiber shedding – keeps the cutting surface clean

- Smooth joint & seamless bonding – ensures stable material feeding

- Uniform thickness – maintains consistent cutting depth

Applications of Felt Conveyor Belts

| Industry | Application Example |

|---|---|

| Textile & Apparel | Fabric pattern cutting, garment sample making |

| Leather Goods | Bags, shoes, and upholstery cutting |

| Automotive Interiors | Floor mats, insulation, dashboards |

| Packaging | Corrugated cardboard, foam board |

| Advertising & Signage | PVC, KT board, acrylic sheets |

| Electronics | Anti-static transport of delicate components |

How to Maintain Your Felt Mat

Regular maintenance can significantly extend the service life of the felt mat and improve cutting accuracy:

- Clean the surface regularly with compressed air or a soft brush.

- Avoid liquid cleaners that may damage the felt fiber.

- Replace worn sections before they become uneven.

- Keep the vacuum adsorption area clear for strong suction.

Why High-Quality Felt Mats Matter

A low-quality felt mat may cause:

- Uneven cutting depth

- Poor adsorption and material shifting

- Faster blade wear

- Reduced production efficiency

Investing in a durable, high-density felt mat ensures consistent cutting precision, longer machine lifespan, and smoother workflow — especially for continuous production environments.

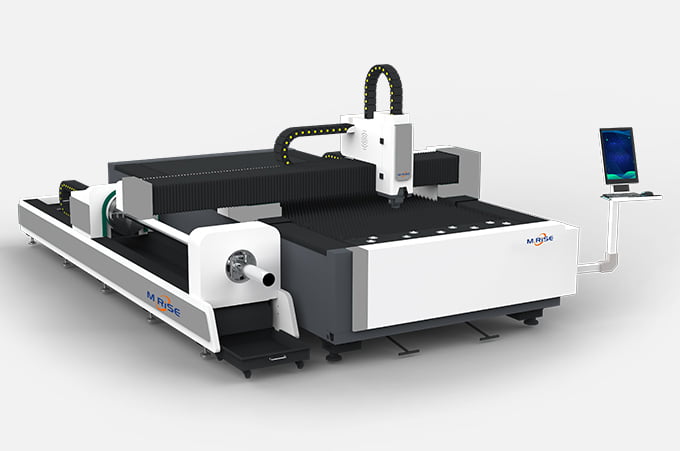

About M.RISE

At Jinan M.RISE Machinery Equipment Co., Ltd., we provide not only CNC oscillating knife cutting machines but also a full range of cutting accessories including:

- Felt conveyor belts (custom sizes)

- Knife blades

- Electric boards and cables

- Vacuum adsorption systems

Our CNC digital knife cutters are CE, FDA, RoHS, and ISO9001 certified, exported to 70+ countries with a 3-year warranty and lifetime support.

We can customize the felt mat size and material based on your cutting table model.

Contact us to get a quote or technical recommendation: