Introduction

Rockwool, also known as stone wool, is widely used for thermal and acoustic insulation in construction and industrial applications. However, cutting Rockwool insulation boards into precise shapes and dimensions can be challenging — especially when the material is thick (2 inches or more) and needs to fit customized panels or curved designs.

Traditional cutting tools generate dust, uneven edges, and material waste.

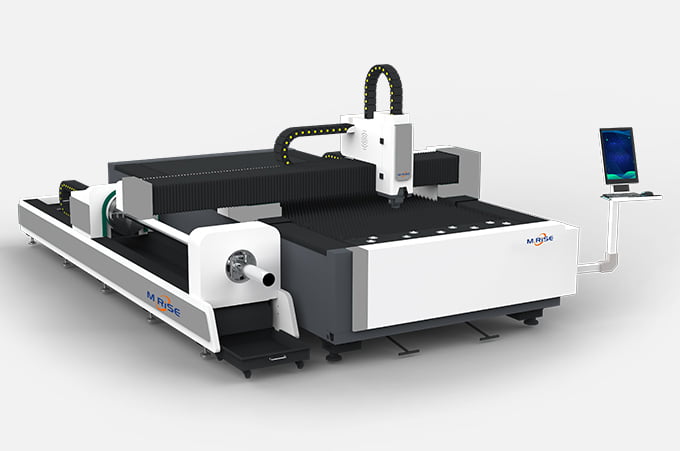

Our CNC Oscillating Knife Cutting Machine provides a clean, efficient, and fully digital cutting solution for Rockwool and other insulation materials.

Cutting Challenges

Rockwool’s fibrous texture makes it difficult to cut accurately using manual or saw-based tools.

Common problems include:

- Dust and fiber scattering during cutting

- Rough edges and inconsistent dimensions

- Slow manual processing speed

- Health and safety risks from airborne fibers

For manufacturers or contractors who process Rockwool in large quantities (e.g., 4 ft × 2 ft boards with 2-inch thickness), automation is the key to improving efficiency and quality.

Our CNC Knife Cutting Solution

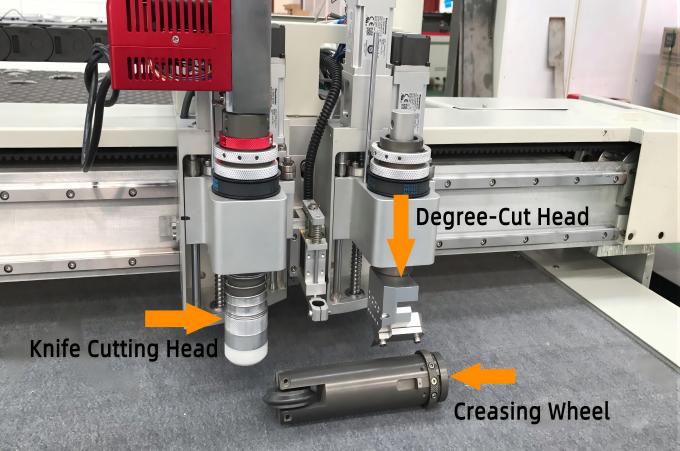

The M.RISE CNC Oscillating Knife Cutting Machine uses high-frequency blade vibration instead of heat or friction, ensuring smooth, dust-free cuts without material deformation.

Key Features:

- Suitable for Rockwool, Glass Wool, Soundproof Cotton, and Foam Insulation

- Supports up to 2-inch (50mm) thick insulation materials or more

- High-precision servo control system ensures consistent cutting accuracy

- Automatic nesting software reduces material waste

- Digital design import (DXF/PLT) for customized shapes

- No smoke, no burn marks, no odor

Optional Add-ons:

- Vacuum suction table for stable fixation

- Multiple cutting tools for different insulation types

- Automatic feeding system for batch production

Benefits for Insulation Manufacturers

- Increased productivity — handle high-volume cutting of Rockwool sheets

- Consistent quality — perfect edges for better fitting and sealing

- Reduced labor cost — fully automatic operation

- Eco-friendly cutting — zero dust and no heat emissions

Whether you produce building insulation panels, soundproof walls, or customized HVAC insulation, this machine offers a cost-effective and clean solution.

Case Study: Mexico Client Cutting 2-Inch Rockwool

Recently, a customer from XX, Mexico reached out to us for a Knife Cutting Insulation Machine to process 2-inch Rockwool insulation (4 ft × 2 ft sheets) into customized shapes.

After technical confirmation, we recommended our CNC Oscillating Knife Cutting Machine with a high-frequency vibration blade, which perfectly matches their production needs.

This real-world case shows how M.RISE provides tailored cutting solutions to global insulation manufacturers.

Conclusion

If your business handles Rockwool or similar insulation materials and you’re looking for a clean, efficient, and precise cutting method, a CNC Oscillating Knife Cutting Machine is your best choice.

Contact M.RISE today to get a free quotation and technical consultation for your insulation cutting solution.