Introduction

In today’s competitive manufacturing world, efficiency and accuracy depend on advanced equipment. From textiles and leather to composites and packaging, manufacturers are seeking smarter cutting solutions. One technology at the center of this progress is the oscillating knife cutting machine, also known as the CNC vibrating knife cutter.

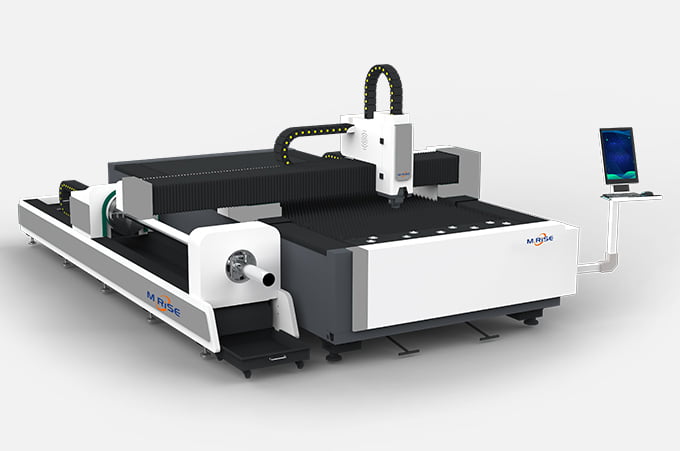

At M.RISE, a trusted Chinese manufacturer with over 10 years of experience, we deliver machines equipped with the latest technology to help global businesses cut faster, cleaner, and smarter.

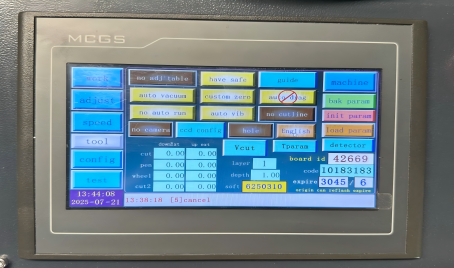

1. Latest CNC Control Technology

With intelligent CNC software, today’s cutters integrate AI-based nesting, toolpath optimization, and real-time monitoring. This latest technology ensures better material utilization, consistent precision, and reduced operator errors.

2. High-Frequency Blade Technology

The latest oscillation systems reach up to 20,000 strokes per minute, producing smooth, burr-free edges on textiles, foams, leathers, and composites. This latest technology not only improves quality but also minimizes material waste.

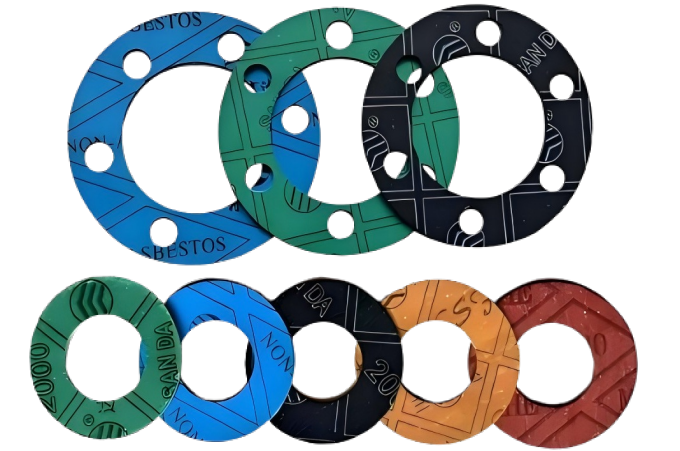

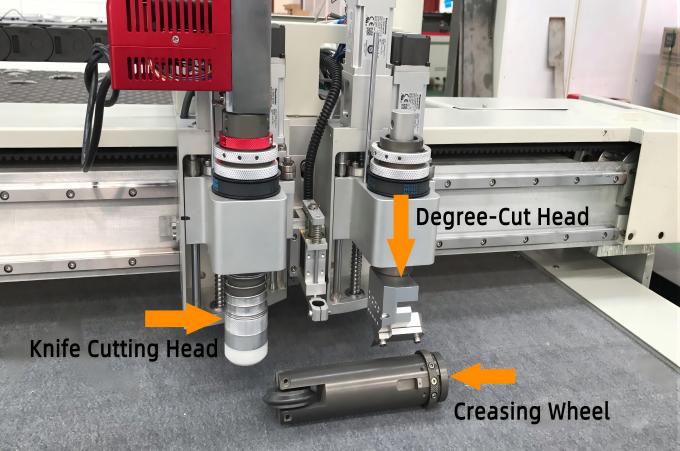

3. Modular & Multi-Tool Technology

The newest cutters support automatic tool-changing systems, enabling quick switching between oscillating blades, drag knives, creasing tools, and rotary cutters. This latest modular technology allows one machine to handle textiles, cardboard, gaskets, plastics, and more—without downtime.

4. Vision & Positioning Technology

Using CCD cameras and laser alignment, the latest positioning technology ensures accurate cutting on printed graphics, labels, or logos. This is critical for industries like advertising, packaging, and apparel manufacturing.

5. Smart Connectivity Technology

IoT-enabled systems and energy-saving servo motors bring the latest technology in connectivity and sustainability. Operators can monitor performance remotely, schedule predictive maintenance, and integrate cutters into digital factory networks.

6. Automated Production Technology

From auto-feeding conveyors to barcode recognition, automation is now part of the latest cutting technology. This allows continuous production with minimal labor, boosting productivity in textiles, automotive interiors, and packaging.

Why Choose M.RISE?

With over 10 years in CNC cutting machine manufacturing, M.RISE has consistently applied the latest technology to ensure high precision, reliability, and cost efficiency. Our oscillating knife cutting machines are designed for long-term performance in textile, leather, composite, and packaging industries.

Conclusion

The latest technology in oscillating knife cutting machines is reshaping industries by combining automation, accuracy, and multi-functionality. From CNC intelligence to smart connectivity, these advancements allow manufacturers to reduce costs and stay competitive.

At M.RISE China, we are proud to provide global customers with state-of-the-art vibrating knife cutters that represent the true latest technology.