Home > Laser Tools and accessories

- Fiber Laser Cutting Machines Consumables

Why Choose M.RISE

Quality Certification

Certified by CE, ISO 9001, FDA, and RoHS, our machines meet the highest standards of quality and safety

OEM/ODM and Customized Solution

We provide customized production line solutions for various industries, backed by an R&D team with over 10 years of experience.

GOLD Warranty

3-Year Warranty,

Free lifetime based TECH support

24/7 Customer Service

Our multilingual team of professional engineers responds within 1 hour and provides both online and on-site paid services for machines from other brands

WHAT OUR CUSTOMERS SAY

GET A QUOTE

Talk to Expert and Get Tailored Cutting Solution Free

Help you to cut smarter, faster, and better

Does fiber laser need gas?

During the fiber laser cutting process, an assist gas blows through a nozzle on the laser cutting head. How much gas is needed can vary, but it’s generally a small amount.

What maintenance does a fiber laser cutter require?

Routine tasks include:

Cleaning protective lens weekly

Checking laser head alignment

Replacing filters (air/dust)

Monitoring water chiller performance

Ensuring dust removal systems are functional

Professional service checks are advised every 6–12 months.

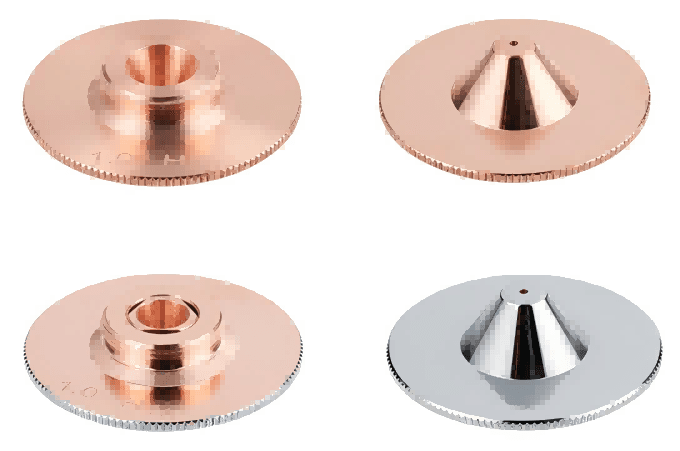

What is the function of the nozzle in a fiber laser cutting machine?

The nozzle directs the assist gas (such as nitrogen or oxygen) precisely onto the cutting area, protecting the lens and improving cut quality by removing molten material efficiently.

What is the difference between single and double nozzle designs?

Single nozzles focus gas directly onto the cutting point, ideal for most applications. Double nozzles provide better protection and gas flow for high-power or thick-material cutting.