Introduction

Modern Automatic CNC Gasket Cutting Machines provide the accuracy and efficiency that today’s valve gasket industry demands.

Unlike conventional gasket cutting equipment, our digital gasket cutter ensures consistent sealing performance.

Key Challenges in Valve Gasket Production

Conventional methods present multiple limitations:

- Inconsistent precision that leads to sealing failures.

- High tooling costs for each new gasket size or shape.

- Slow production cycles for small batches or urgent orders.

- Material waste due to poor nesting and manual handling.

These challenges highlight the need for an automatic gasket cutting solution, where a CNC gasket cutter ensures repeatable precision without costly tooling.

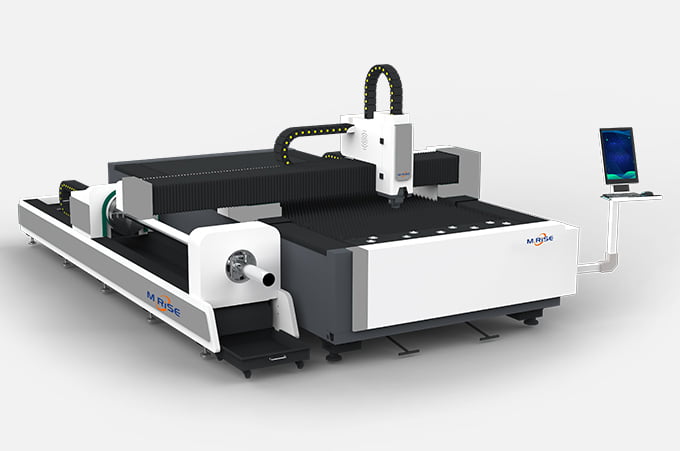

Why M.RISE Automatic CNC Gasket Cutting Machine Stands Out

Our Automatic CNC Gasket Cutting Machine is purpose-built for valve gasket manufacturing, offering unmatched flexibility compared to traditional gasket cutting equipment.

Designed with valve gasket applications in mind, our system delivers:

- CCD camera positioning for pinpoint cutting accuracy, even with complex patterns.

- Automatic feeding to reduce manual handling and boost throughput.

- Intelligent nesting software for maximum material utilization and cost savings.

- Direct CAD-to-cutting workflow, eliminating molds and reducing lead times.

Technical Specifications

Our CNC gasket cutting machine combines robust hardware with intelligent software:

- Working table size: 1600 × 2500 mm – handles large-format gasket sheets.

- Cutting speed: 0–1600 mm/min – balancing precision with productivity.

- Maximum cutting thickness: up to 16 mm – suitable for a wide range of gasket materials.

- Software compatibility: AutoCAD, CorelDRAW, and CAM – smooth integration with your existing design process.

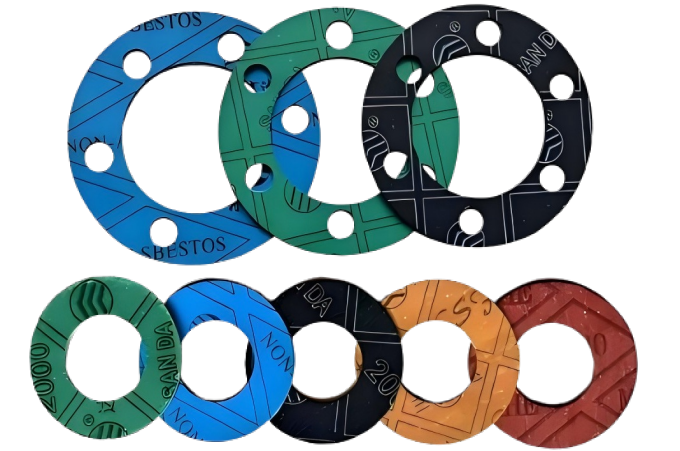

Supported Materials

The machine is engineered for industrial gasket cutting, capable of processing graphite gaskets, rubber gaskets, PTFE gaskets, non-asbestos gaskets, fiber-reinforced gaskets, and polyurethane gasket sheets, including:

- Graphite sheets

- Rubber (NBR, EPDM, Viton)

- PTFE and expanded PTFE

- Non-asbestos compressed fiber (CNAF)

- Fiber-reinforced composites

- Polyurethane and other engineered sheets

This makes it the ideal gasket manufacturing machine for valve producers seeking reliable and flexible sealing solutions.

Benefits for Valve Manufacturers

Adopting our CNC gasket cutting machine brings measurable advantages:

- Leak-proof sealing through highly accurate cutting.

- Faster delivery thanks to automatic feeding and optimized nesting.

- Flexibility to handle custom sizes, complex geometries, and different material types.

- Lower production costs by reducing waste and eliminating expensive tooling.

- Consistent quality assurance across every gasket produced.

Free Sample Cutting & Global Service

To help you evaluate performance, we offer free sample cutting and material testing. Simply send us your material, and we will cut and return samples for verification. Our global support team provides installation guidance, operator training, and responsive after-sales service to ensure smooth operation.

Conclusion

In the valve industry, where safety and reliability are non-negotiable, precision-cut gaskets are essential.

With CCD positioning, automatic feeding, and intelligent nesting, the M.RISE Automatic CNC Gasket Cutting Machine is the go-to solution for modern industrial gasket cutting and valve gasket manufacturing.

Ready to improve your gasket production? Contact us today for a free sample cutting test and experience the difference.