Introduction

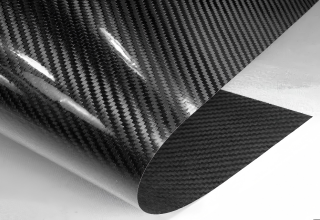

Cutting uncured carbon fiber prepreg into accurate patterns is one of the most critical steps in composite manufacturing. Whether in aerospace, automotive, or sporting goods, engineers need a cutting solution that offers precision, repeatability, and clean edges—without fiber distortion or resin contamination.

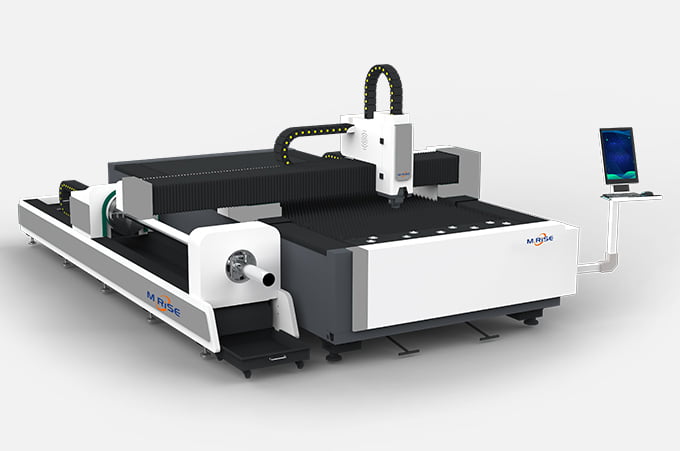

Traditional cutting methods, such as manual trimming or hot tools, often fall short. That’s where a CNC Oscillating Knife Cutter comes in. In this guide, we’ll explore how this technology solves the unique challenges of prepreg cutting and what you should look for when selecting a machine.

Why Carbon Fiber Prepreg is Difficult to Cut

Uncured thermoset prepreg is unlike standard fabrics:

- Tacky surface: makes handling and cutting difficult.

- Release backing paper: must stay intact during cutting.

- Fiber orientation: requires precise cutting to maintain performance.

- Heat sensitivity: excludes laser cutting due to risk of resin damage.

These factors demand a non-thermal, precision cutting solution—which is exactly what oscillating knife cutters provide.

Machine Requirements for Cutting Prepreg

1. Cutting Accuracy

- High-performance applications require ±0.5 mm or better accuracy across the full cutting area. This ensures parts fit perfectly in layup and molding stages.

2. Work Area

- A typical configuration is 1600 × 2500 mm, suitable for 1-meter-wide rolls of carbon fiber prepreg and handling up to ~3 m² at a time.

3. Tooling Options

- Oscillating/tangential knife: best for straight and complex contours.

- Rotary wheel knife: ideal for continuous cuts and reducing fiber pull.

4. Vacuum Hold-Down System

- Because prepreg is tacky, a reliable vacuum table is essential. Look for:

- Zone control to optimize suction power.

- Industrial vacuum pump with sufficient capacity for large plies.

5. Software Integration

Efficient use of expensive composite material requires smart software:

- Automatic nesting for material optimization.

- Pattern management for multiple part designs.

- Compatibility with CAD/CAM files.

6. Vision System

A CCD camera can register fiducials and align patterns, ensuring accuracy even with material stretch or misalignment.

7. Accessories

- Cutting underlay materials to prevent tool wear and protect backing paper.

- Specialty blades recommended for tacky prepreg.

Benefits of Oscillating Knife Cutting for Prepreg

- No heat damage compared to laser cutters.

- High precision and repeatability for aerospace-grade components.

- Tool versatility for different ply thicknesses and weave styles.

- Scalable from prototyping to production.

- Reduced waste thanks to nesting software.

Recommended Blades and Cutting Underlay

- Carbide-tipped oscillating blades for long life in tacky materials.

- Rotary knives for continuous cuts with less fiber displacement.

- Self-healing cutting mats or sacrificial underlay sheets to maintain accuracy and prolong blade life.

Sample Cutting and Testing

Before investing in a cutting machine, it is best practice to:

- Send your material rolls and CAD pattern files to the supplier.

- Request a sample cut test and cutting video demonstration.

- Verify that the machine meets accuracy, edge quality, and productivity expectations.

Conclusion

Carbon fiber prepreg cutting requires more than a standard fabric cutter. With a CNC Oscillating Knife Cutting Machine, manufacturers gain the precision, consistency, and process reliability needed for demanding composite applications.

Whether you’re prototyping aerospace parts or scaling up for automotive production, oscillating knife technology offers the optimal solution for cutting uncured carbon fiber prepreg.

Contact us today to request a brochure, pricing, or to arrange a free sample cutting test with your own material.