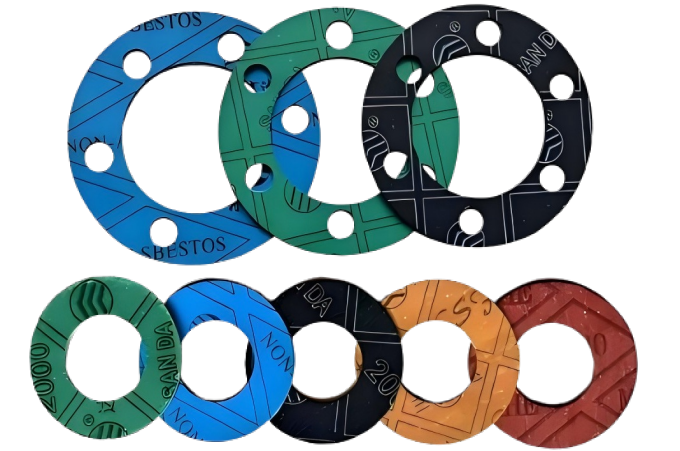

Asbestos gaskets are widely used in industrial sealing applications where precision, reliability, and dimensional stability are critical. From oil and gas pipelines to automotive engines and industrial equipment, gasket quality directly affects sealing performance and operational safety.

Choosing the right cutting technology is therefore a key decision for gasket manufacturers.

This article explains how CNC vibrating knife cutting technology is applied to asbestos gasket manufacturing, compares it with other cutting methods, and introduces a proven industrial solution used in real production environments.

What Is an Asbestos Gasket Cutting Machine?

An asbestos gasket cutting machine is a CNC-controlled system designed to cut asbestos-based sealing materials into precise gasket shapes according to digital drawings. Unlike traditional mechanical cutting or thermal processes, modern CNC systems focus on accuracy, repeatability, and flexibility.

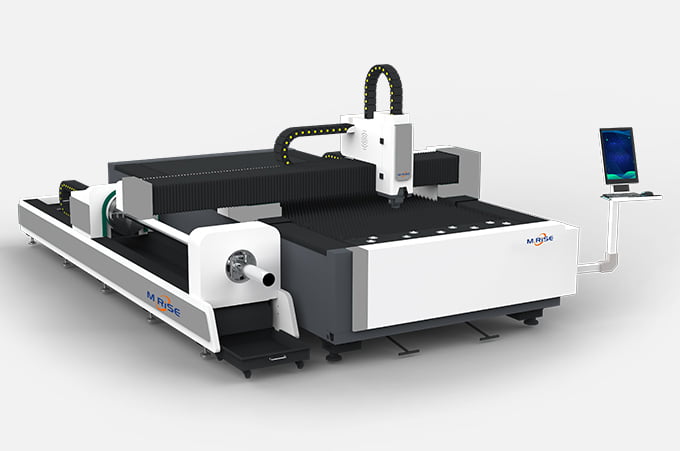

The MR-1625 CNC Asbestos Gasket Cutting Machine is designed for industrial gasket production, supporting both standard and customized gasket designs without the need for molds or dies.

Key Specifications of the MR-1625 CNC Asbestos Gasket Cutting Machine

The MR-1625 model is engineered to meet the requirements of medium- and large-format gasket manufacturing.

Main Specifications:

- Working Area: 2500 × 1600 mm

- Cutting Speed: 50–1500 mm/s

- Cutting Accuracy: ±0.1 mm

- Material Thickness: 1–20 mm

- Control System: Zhongrui Control System

- Operating Software: Xiao Software

- Tool Options: Vibrating blade tool, Pneumatic blade tool, Punching tool

- Compatible Materials: Asbestos gaskets, Rubber gaskets, Industrial sealing materials

These specifications allow the system to handle complex gasket profiles while maintaining consistent quality across batches.

How Vibrating Knife Cutting Technology Works

Vibrating knife cutting is a cold-cutting CNC technology in which the blade oscillates at high frequency while following a programmed cutting path. The vibration reduces cutting resistance and allows the blade to pass smoothly through dense or fibrous materials.

For asbestos gasket materials, this method offers several technical advantages:

- No heat generation during cutting

- No edge burning or material hardening

- Clean, smooth edges with minimal burrs

- Stable cutting force for consistent dimensions

Because asbestos-based materials are sensitive to thermal stress, non-thermal cutting methods are generally preferred in industrial applications.

Vibrating Knife vs Laser, Waterjet, and Punching

Different cutting technologies are commonly used in gasket production, each with its own limitations.

- Vibrating Knife vs Laser Cutting

Laser cutting introduces heat, which may cause: Material deformation, Edge carbonization, Potential safety concerns when processing asbestos materials.

Vibrating knife cutting avoids thermal effects entirely, making it more suitable for asbestos gaskets. - Vibrating Knife vs Waterjet Cutting

Waterjet cutting requires: High energy consumption, Abrasives and water treatment systems, Higher operational and maintenance costs.

CNC vibrating knife systems offer lower operating costs and simpler daily maintenance. - Vibrating Knife vs Traditional Punching

Punching methods depend on fixed molds, which: Increase tooling costs, Limit design flexibility, Are inefficient for small batches or custom orders.

CNC cutting enables mold-free, digital production, allowing rapid design changes.

Why Vibrating Knife Cutting Is Ideal for Asbestos Gaskets

Asbestos gasket manufacturing demands:

- High dimensional accuracy

- Smooth sealing edges

- Production consistency

- Improved operational safety

With a cutting accuracy of ±0.1 mm, the MR-1625 CNC Asbestos Gasket Cutting Machine meets these requirements while supporting flexible production workflows. Multi-tool configurations also allow punching holes and contour cutting in a single setup, improving overall efficiency.

Industry Applications

CNC asbestos gasket cutting machines are widely used across multiple industries.

Industrial Equipment Sealing

- Pumps, compressors, and pressure vessels

- Custom gasket profiles for heavy machinery

Automotive and Railway Sealing

- Automotive engine gaskets

- Locomotive and railway sealing components

Oil, Gas, and Energy Industries

- Pipeline flange gaskets

- Valve and sealing components

Mechanical Equipment Manufacturing

- OEM gasket production

- Customized sealing solutions for industrial equipment

The ability to switch designs digitally makes CNC cutting especially valuable for manufacturers serving multiple industries.

Production Efficiency and Cost Benefits

Compared with manual cutting or traditional punching methods, CNC vibrating knife cutting machines can significantly improve productivity.

Key benefits include:

- Up to 30% improvement in production efficiency

- Reduced material waste

- Lower labor dependency

- Faster order turnaround times

These advantages make CNC gasket cutting a practical long-term investment for modern manufacturers.

Frequently Asked Questions

Can a vibrating knife cut asbestos gaskets?

- Yes. Vibrating knife cutting is a non-thermal process and is well suited for asbestos gasket materials requiring clean edges and high precision.

Can the machine cut multi-layer gasket materials?

- Yes. The MR-1625 supports both single-layer and multi-layer cutting within a thickness range of 1–20 mm.

What is the cutting accuracy?

- The system achieves a cutting accuracy of ±0.1 mm, suitable for industrial sealing applications.

Is operator training complicated?

- No. With the Zhongrui control system and Xiao software, operators can quickly learn basic operation through standard CNC training.

Conclusion

CNC vibrating knife cutting technology has become an important solution for modern asbestos gasket manufacturing. By combining digital control, non-thermal cutting, and high precision, it helps manufacturers improve product quality while reducing production costs and operational complexity.

As industrial sealing requirements continue to increase, selecting the right gasket cutting technology is no longer just a technical decision—it is a strategic choice for long-term manufacturing efficiency.