Composite Materials Industry Cutting Application

Home > CNC Vibrating Knife Cutting for the Composite Materials Industry

CNC Vibrating Knife Cutting for the Composite Materials Industry

Oscillating Knife Cutting Video

1. Introduction

Composite materials—such as carbon fiber prepreg, fiberglass, aramid, and honeycomb structures—are widely used across aerospace, automotive, marine, and sports industries. These materials are known for their high strength-to-weight ratio, durability, and flexibility, but they also pose challenges during processing due to their layered or reinforced structures.

Our CNC Vibrating Knife Cutting Machines provide a precise, clean, and efficient solution for cutting a wide range of composite materials without fraying, delaminating, or generating dust. Whether you’re processing prepreg fabrics, soft laminates, or thick insulation composites, our machines deliver the accuracy and reliability your production demands.

2. Materials Supported

Carbon Fiber Prepregs (PAN-based, pitch-based, viscose-based), Glass Fiber Prepregs, Aramid/Kevlar, CFRP/GFRP

3. Machine Features

- High-frequency oscillating knife

Cleanly slices through fiber-reinforced materials without causing burn marks or tool wear. - Multi-tool configuration

Optional rotary blades, kiss-cut tools, creasing wheels, and V-cut tools can be installed for complex processing needs. - Heavy-duty vacuum table

Ensures firm material fixation, especially for slippery or rolled composite surfaces. - Smart conveyor feeding (optional)

For continuous cutting of roll-fed composite fabrics such as fiberglass or carbon prepreg. - Automatic nesting software

Minimizes waste and optimizes material usage, essential for costly composite stock. - Safety and precision sensors

Guarantee operator safety and ensure dimensional accuracy even with intricate shapes.

4. Benefits

- Non-contact cutting

No melting, scorching, or dust emissions—ideal for cleanroom or prepreg environments. - Material versatility

Cuts everything from flexible composite fabrics to semi-rigid sheets and sandwich panels. - High-speed productivity

Dual-head and conveyor models available for 24/7 high-throughput production. - Zero-tooling setup

Switch jobs quickly and easily—perfect for custom or short-run composite parts. - Perfect for difficult materials

Cuts through Kevlar, aramid, carbon, and glass fiber fabrics with ease.

5. Applications

- Aerospace interior panels and insulation

- Carbon fiber parts for drones, bicycles, and race cars

- Fiberglass boat components and marine insulation

- Wind turbine blade materials

- Automotive reinforcement layers and headliners

- Protective clothing and composite armor layers

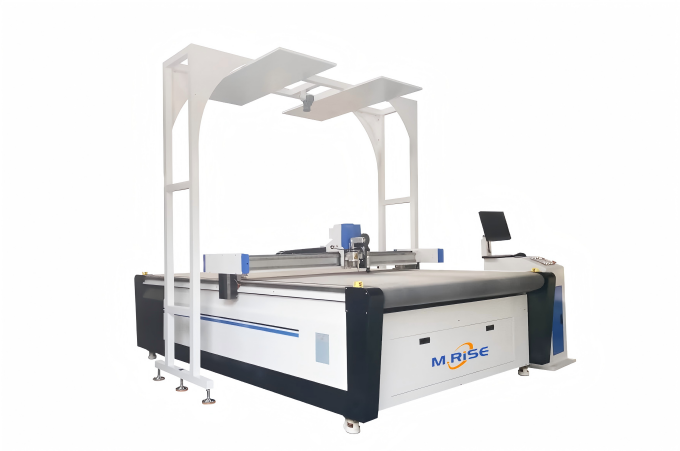

6. M.Rise Computer Carbon Fiber Prepreg Cutting Machine

Designed for high-precision cutting of carbon fiber, fiberglass, and aramid composites. Its robust structure supports multi-layer cutting of thick, dense composite sheets without deformation. Ideal for automotive, marine, and aerospace applications where consistency and speed are critical.

GET A QUOTE

Talk to Expert and Get Tailored Cutting Solution Free

Whether you’re exploring options or ready for a quote, our team is ready to support you with honest answers and fast service.Tell us what you need—just one minute to get started.