When it comes to cutting PVC tarpaulin — a material commonly used for industrial and commercial purposes — utilizing a CNC cutting machine, specifically a CNC oscillating knife cutting machine, can provide numerous advantages. In this article, we’ll explore how this technology can elevate PVC tarpaulin cutting, the benefits of CNC machines, and why it’s a crucial investment for manufacturers in the industry.

What is a CNC Oscillating Knife Cutting Machine?

A CNC oscillating knife cutting machine is an advanced automated cutting system designed to handle flexible, non-metal materials like PVC, fabrics, rubber, foam, and tarpaulin. The machine uses a high-frequency oscillating knife to slice through materials with precision, ensuring clean cuts without fraying or damaging the material.

For manufacturers working with PVC tarpaulin, CNC cutting technology provides a solution that can dramatically improve cutting speed, quality, and consistency. Unlike traditional methods, CNC machines are controlled by computer software, allowing for highly accurate and repeatable results.

Why Choose CNC Oscillating Knife Cutting Machines for PVC Tarpaulin?

- Precision Cutting for PVC Tarpaulin

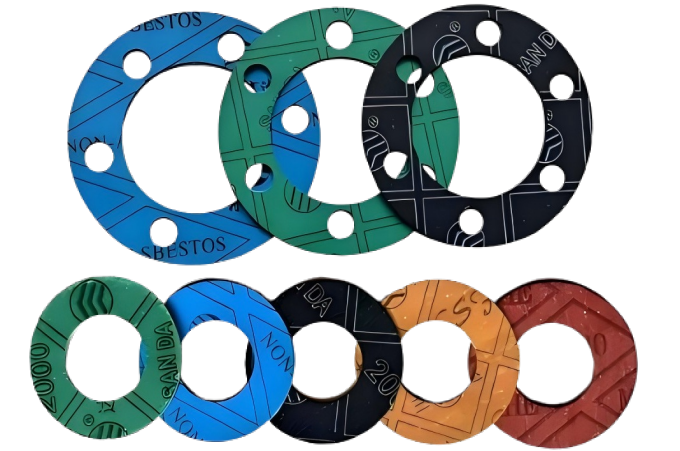

PVC tarpaulin is often used in products that require high durability, such as tarpaulin covers, banners, or industrial applications. CNC oscillating knife cutting machines provide extreme accuracy, ensuring clean cuts with tight tolerances. This precision is essential in maintaining the structural integrity of PVC tarpaulin, especially for applications that require specific dimensions. - Increased Cutting Speed

High-speed cutting is critical for manufacturers who need to maximize throughput. CNC cutting machines are capable of cutting large volumes of PVC tarpaulin at a faster rate than manual cutting, significantly improving productivity and reducing labor costs. - Versatility and Flexibility

CNC oscillating knife cutting machines are versatile. They can cut a wide range of flexible materials, including various grades of PVC tarpaulin, fabrics, rubber, and more. This versatility means manufacturers can handle multiple production requirements without needing different machines for each material. - Minimized Material Waste

The precise cutting capabilities of CNC machines ensure that minimal material is wasted during production. By optimizing material usage, manufacturers can lower production costs and improve overall profitability. - Customization and Automation

CNC machines can be programmed to cut PVC tarpaulin into any shape or design, which is especially useful for custom orders. The automation provided by the system minimizes human error and reduces downtime, allowing for a smoother and more efficient production process.

CNC Oscillating Knife Cutting Machines in PVC Tarpaulin Production

CNC oscillating knife cutting machines play a significant role in various stages of PVC tarpaulin production. These machines are specifically designed for cutting flexible PVC tarpaulin, fabric, rubber, and foam materials. Whether you’re producing large custom pieces or smaller, more detailed cuts, CNC machines ensure that every product is cut with the highest level of precision and efficiency.

Some common applications include:

- Tarpaulin Covers: Accurate cutting of PVC tarpaulin into desired sizes for use in protective covers, tents, and more.

- Banners and Advertising Materials: CNC machines can also be used for cutting printed PVC tarpaulin used in large-scale advertising and signage.

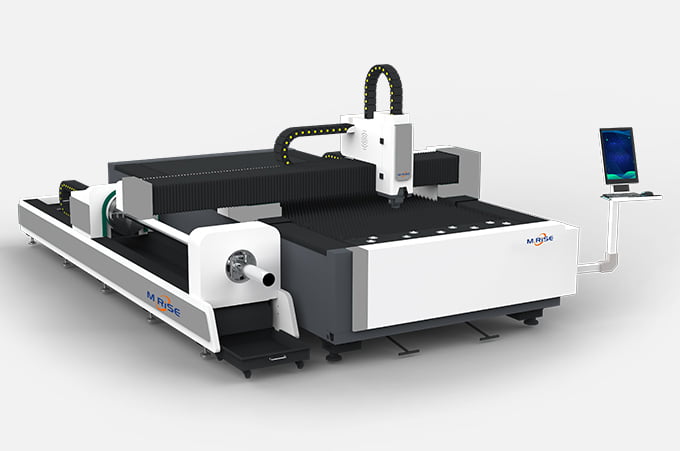

How M.RISE CNC Oscillating Knife Cutting Machines Can Help Manufacturers

At M.RISE Machinery, we specialize in providing CNC cutting solutions for flexible materials like PVC tarpaulin. Our CNC oscillating knife cutting machines are designed to meet the demands of high-speed manufacturers. Here’s how our solutions can support your business:

- Fast Delivery and High Capacity: With a monthly production capacity of up to 300 units and a delivery time of 7 days for stock machines, we ensure that your production needs are met with quick turnaround times.

- Reliable and Precise Cutting: Our machines are designed for high precision, ensuring consistent and accurate cuts on PVC tarpaulin, enhancing the quality of your finished products.

- 3-Year Warranty and Lifetime Support: All of our machines come with a 3-year warranty and lifetime technical support, ensuring you receive continuous service throughout the lifecycle of the machine.

- CE and ISO Certifications: Our cutting machines are CE, FDA, RoHS, and ISO9001 certified, ensuring that they meet international safety and quality standards.

Conclusion: A Smart Investment for Future Growth

Investing in a CNC oscillating knife cutting machine for PVC tarpaulin will provide a significant boost in terms of cutting speed, precision, and overall production quality. At M.RISE Machinery, we offer state-of-the-art solutions backed by a 3-year warranty and lifetime technical support, ensuring that your production runs smoothly for years to come.

Contact us today to learn more about how our CNC cutting machines can revolutionize your PVC tarpaulin production process!