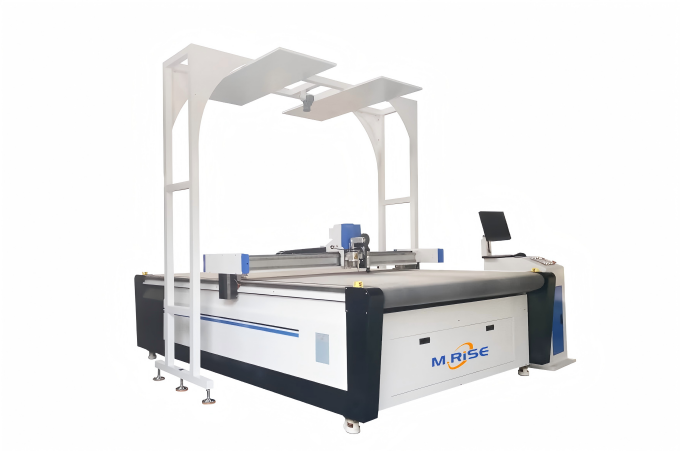

Leather Digital Knife Cutter

Home > CNC Leather Cutting Machine

CNC Leather Cutting Machine for Precision Leather Processing

Cutting Materials:

Leather, Fabric, Textiles, Carpets, Foot Mats, Leather Seats, Lining, Tail Box Pads, Car Seat Cushions

Supply Capacity:

300 Sets Available per Month

Delivery:

7 Days

Certificate:

CE Certified for Quality and Safety

Warranty:

3-Year Warranty + Lifetime Free Technical Support

Payment Term:

Online (PayPal, Alibaba Trade Assurance) / Offline (T/T, Credit or Debit Card)

Product Presentation

CNC Leather Cutting Machine Description

Revolutionize Your Leather Cutting with M.RISE Digital Cutting Solutions

Tired of inconsistent hand cuts, wasted materials, and costly dies? M.RISE brings a smarter way to craft with our next-generation digital leather cutter machines, designed for precision, speed, and total production efficiency.

Whether you’re producing fine handbags, durable footwear, or custom leather accessories, M.RISE ensures clean, accurate cuts every time—without the need for traditional molds or extensive manual labor. Our machines are engineered to handle a wide variety of materials including genuine leather, sole, lining, and pattern sheets, all while delivering up to 80% productivity gains.

What sets M.RISE apart?

Precision that Elevates Craftsmanship – Achieve flawless edge quality and dimensionally accurate cuts, critical for luxury-level finishing.

No Dies, No Waste – Go from design to production without the cost or delay of physical dies.

Labor-Efficient Workflow – Reduce reliance on manual cutting while maximizing material yield.

High-Speed Output with Low Operational Cost – Boost your ROI with every production run.

CNC Leather Cutting Machine Details

Multi -tools Blade Cutting Head

◆ EOT-Electric Oscillating Tool is widely used in all flexible materials cutting, such as fabric, cloth, leather ect.

◆ EOT+ROT+CCD+Marking Pen

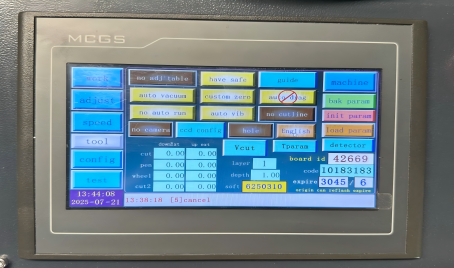

CNC Intelligent Control System

◆ Touch screen for easy operation

◆ Multi-language mode: English, Korean, Spanish, Portuguese, Turkish, etc.

Servo Motor and Driver

◆ To make sure fast moving speed and cutting speed with stable situation

◆ The MAX cutting speed is 1600mm/s, 3-5 times than traditional cutting.

High-density Felt Countertops

◆ The felt contains metal wire, suitable for automatic feeding table and durable very much

Aluminum Vacuum Adsorption Table

◆ The heavy-duty welding bed and aluminum vacuum adsorption platform ensure stability during high-speed cutting.

◆ The adsorption platform can fix the material and ensure cutting accuracy.

Zoned Exhaust System

◆ The platform is divided into many areas for ventilation work to ensure that the adsorption platform works well during cutting.

Big Camera for Printed Mateirals Cutting

◆ If The camera is using for printed materials cutting.

◆ This big camera can recognize graphics and generate drawings, transmit them to the control system, and then perform precise cutting.

Projector as Option

◆ Using digitalized production equipment, you can produce high-quality products, control and reduce waste based on demand.

◆ For more precise cutting, the projector can project the drawing onto the material to be cut.

Standard Bracket of Roll Materials

◆ The rack could support materials in roll like fabric, leather, textile ect. to match with auto loading worktable for cutting.

◆ Multiple brackets can be placed to meet multi-layer cutting needs

Automatic Correction Feeding Rack

◆ Auto loading bracket with auto correcting the fabrics in roll function, to cooperate with auto loading worktable.

◆ Save labor cost, save time and high precision.

Laminating Device for Film

◆ When the breathable material cannot be vacuum-absorbed, a fully automatic laminating device is required to fix the fabric and ensure cutting accuracy.

◆ Essential for cutting multi-layer fabrics

High-power Exhaust Fan

◆ High-power fan supports partition adsorption function, with stronger adsorption force

CNC Leather Cutting Machine Parameter

No.

Item

Parameter

1

Machine Model

MR-1625K/1830K/2130K

2

Tube Cutting Size

1600*2500mm(63 x 98.4''), 1800*2500mm(70.9 x 98.4''), 2100*3000mm(82.7 x 118.1'')

4

Cutting Speed

100-1600mm/s

5

Cutting Thickness

0.1-100mm (Adjustable based on materials and requirement)

6

Cutting Accuracy

±0.01 mm

7

Positioning Accuracy

±0.01 mm

8

Cutting Materials

Leather, Genuine, Cowhide, Fabric, Textile, Non-woven Fabrics, Carton, Corrugated Paper, Honeycomb Board, Rubber, Plastic, Gasket, PVC, Grey Board, Paper, Composite Board, Foam Board, EVA Foam, PU Foam, PE Foam, ect.

9

Cutting Tools

Oscillating blade head, V-cut, Kiss-cut, Creasing wheel, Milling head, Pneumatic Blade head, Marking pen, Punching, ect.

10

Application Pen Type

Common signing pen, Oil pen, Ball-point pen, Silver pen

11

Table Fixed Type

Vacuum worktable/Zoned adsorption platform

12

Rack and Linear Guide

Taiwan

13

Motor and Driver

Servo Type

14

Machine Base

Welded squre metal tube of heavy duty

15

Lubrication System

Automatic Lubrication

16

Control Software

Zhongrui

17

Support Files Format

PLT, AI, CDR, HPG, HPGL, ect.

18

Option Parts

Big Camera, Projector, Leather recognition intelligent system, Automatic deviation correction loading rack

GET A QUOTE

Talk to Expert and Get Tailored Cutting Solution Free

Help you to cut smarter, faster, and better

FAQs

- The machine could cut all knids of leather materials, such as Double-faced leather, bonded leather, genuine leather, saddle leather, cowhide, ect;

- At the same time, it could cut all flexible materials to apply in different industries, such as shoes, bags, garment, carton boxes, composite materials, automotive industries, etc.

- Please tell us what materials would you like to cut and the size(Length*Width), we will provide professional suggestions depends on your detail cutting requirements;

- Highly appreciate if you send some materials to us for cutting test, we will record with videos to show you cutting progress and results.

- Most machines utilize software that translates digital designs into precise cutting instructions. This ensures accuracy and eliminates human error, even for complex patterns.

- Common safety features include emergency stop buttons, protective guards around the cutting head, and automatic shut-offs when sensors detect any issues.

- We already gained CE, ISO and TUV certificates, ect.

- We provide free installation and training online.

- Our engineer will help to install the machine at your factory if necessary.

- Regular cleaning and lubrication are essential, but most machines offer user-friendly maintenance routines. Some models even have automated cleaning mechanisms.

- The ROI varies depending on factors like production volume, labor costs, and material savings. However, many businesses see a significant return on investment within a short period due to increased efficiency and reduced waste.

- All machines are relatively user-friendly and require minimal training. We offer training resources and support to ensure smooth operation.

- 1 year of whole machine;

- Free technicial support and software updating of lifetime;

- Repair parts and consumables that need to be replaced are provided to customers at dealer prices.