Advertising Digital Cutting Table

Home > CNC Advertising Cutting Machine

CNC Advertising Cutting Machine

Cutting Materials:

Paper, Vinyl, KT Board, Corrugated Cardboard, Foam, PVC, Acrylic, etc.

Supply Capacity:

300 Sets Available per Month

Delivery:

7 Days

Certificate:

CE Certified for Quality and Safety

Warranty:

3-Year Warranty + Lifetime Free Technical Support

Payment Term:

Online (PayPal, Alibaba Trade Assurance) / Offline (T/T, Credit or Debit Card)

Product Presentation

CNC Advertising Cutting Machine Description

One Machine. Infinite Possibilities. Zero Mold Cost

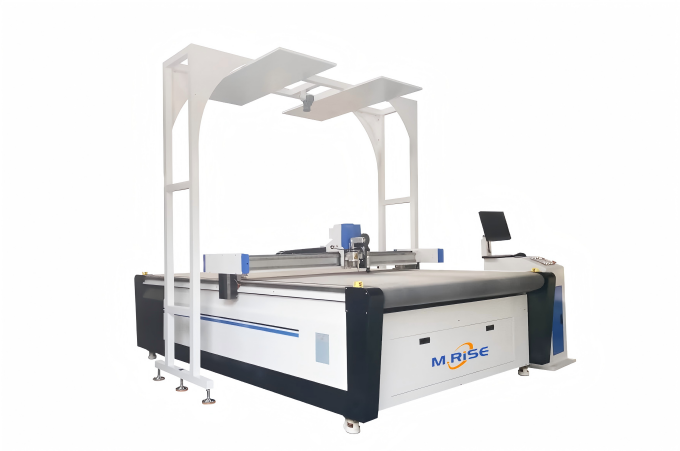

Are you searching for a smarter way to cut signage, displays, and packaging materials? The M.RISE CNC Advertising Cutting Machine is the high-performance, digital solution that eliminates the need for molds and manual trimming — enabling fast, precise, and professional cutting across a wide variety of advertising and packaging materials.

Multi-Tool Cutting Head for All Your Creative Needs

The M.RISE machine features a modular, multi-functional tool head, equipped with a range of cutting and processing tools to meet the needs of different applications in the signage, printing, and packaging industries:

- Oscillating Knife – for fast, clean cuts on soft and semi-rigid materials

- Creasing Wheel – for perfect folding lines on cardboard and paperboard

- V-Cut Tool/Tangential Knife – adjustable groove angles (0°, 15°, 22.5°, 30°, 45°) for display structures

- High-Speed Milling Head/Router – for precise cuts on hard materials like acrylic and PVC

- CCD Camera Positioning – for accurate contour cutting and printed material alignment

Key Features & Benefits

- Wide Material Compatibility

Easily handle corrugated board, Chevron board, KT board, gray board, PVC foam board, acrylic sheets, honeycomb board (30-60mm), car vinyl, self-adhesive materials, photo frame board, rubber sheet, cloth, aluminum composite panels, and more. - True Die-Free Cutting

Eliminate expensive die-making and reduce lead time. Start cutting instantly from digital files. - Seamless Software Integration

Supports CorelDRAW, Adobe Illustrator, AutoCAD and other industry design tools (DXF, PLT, AI formats). - Flexible Cutting Modes

Full cut, half cut, creasing, marking, engraving, perforating, and V-grooving — all in one go. - Smart Efficiency Boost

Up to 5× faster than manual processing

Reduces labor by over 10% annually

Delivers consistent, accurate results

Saves electricity and boosts throughput

Applications Across Advertising & Packaging

- Signage & Display

Cutting KT board signs, POP/POS displays, foam board graphics, acrylic signage, exhibition panels. - Packaging

Rapid prototyping of custom boxes, folding cartons, gift boxes, and printed corrugated packaging. - Print Shops & Graphic Studios

Contour cutting of printed self-adhesive vinyl, labels, film, and cardboard with camera-guided precision. - Custom Creative Projects

Perfect for short-run production of cardboard furniture, 3D display props, and promotional materials.

Designed for the Demands of Modern Production

Whether you’re a sign-making business, packaging supplier, print house, or marketing agency, the M.RISE digital cutting system helps you scale up without scaling your costs.

- Mold-free Operation – Cut immediately from design files

- Fast Turnaround – High cutting speed and workflow automation

- All-in-One Machine – Punching, creasing, cutting, and V-grooving

- Future-Ready – Ideal for small batch, custom, and personalized orders

CNC Advertising Cutting Machine Details

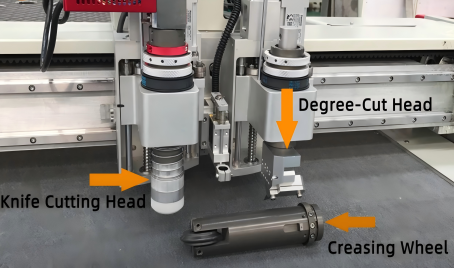

EOT+Degress Cut Head+Creasing Wheel

◆ The EOT for fast, clean cuts on soft and semi-rigid materials

◆ The Creasing Wheel is for perfect folding lines on cardboard and paperboard

◆ Degree-cut Head is adjustable groove angles (0°, 15°, 22.5°, 30°, 45°) for display structures

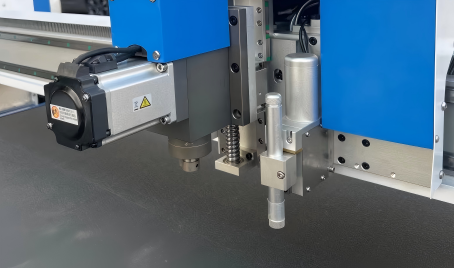

Kiss-cut and Marking Pen

◆ Kiss cutting of car stickers, 3M stickers, and various advertising decals

◆ Marking pen is using for mark on the board sometimes

High Speed Milling Tool

◆ For precise cuts on hard materials like acrylic and PVC

CCD Camera for Positioning

◆ For accurate contour cutting and printed material alignment

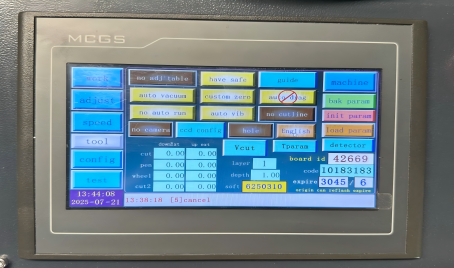

CNC Intelligent Control System

◆ Touch screen for easy operation

◆ Multi-language mode: English, Korean, Spanish, Portuguese, Turkish, etc.

Servo Motor and Driver

◆ To make sure fast moving speed and cutting speed with stable situation

◆ The MAX cutting speed is 1600mm/s, 3-5 times than traditional cutting.

Aluminum Vacuum Adsorption Table

◆ The heavy-duty welding bed and aluminum vacuum adsorption table ensure stability during high-speed cutting.

◆ The adsorption platform can fix the material and ensure cutting accuracy.

Zoned Exhaust System

◆ The platform is divided into several areas for ventilation work to ensure that the adsorption platform works well during cutting.

High-power Exhaust Fan

◆ High-power fan supports partition adsorption function, with stronger adsorption force cutting accuracy.

High-density Felt Countertops

◆ The felt contains metal wire, suitable for automatic feeding table and durable very much

High Camera for Orinted Mateirals Cutting

◆ If you’re working with patterned or pre-printed materials, you’ll know that the pieces can only be assembled accurately if they are cut accurately. Optical detection system ensures highest accuracy.

Projector as Option

◆ Using digitalized production equipment, you can produce high-quality products, control and reduce waste based on demand.

Different Blades to Match with Different Tools

◆ Oscillating blade head to match different baldes for different materials.

◆ Such as V-cut, Half-cut, Creasing Wheel, Milling head, Pneumatic Blade head, ect.

Auto Loading Worktable for Option

◆ Auto loading system match with auto feeding worktable, auto correcting the materials.

CNC Advertising Cutting Machine Parameter

No.

Item

Parameter

1

Machine Model

MR-1625

2

Cutting Size

1600*2500mm(63 x 98.4''), 1800*2500mm(70.9 x 98.4''), 2100*3000mm(82.7 x 118.1'')

4

Cutting Speed

100-1600mm/s

5

Cutting Thickness

0.1-50mm (Adjustable based on materials and requirement)

6

Cutting Accuracy

±0.01 mm

7

Positioning Accuracy

±0.01 mm

8

Cutting Materials

Soft Glass, Sticker, Thin Plastic, Billboard Canvas, Cardboard, Foam Board, Acrylic Board, PP Hollow Board, Aluminum-plastic Panel, Honeycomb Cardboard, Soft Film, Card Paper

9

Cutting Tools

Oscillating blade head, V-cut, Tangential Knife, Router, Kiss-cut, Creasing wheel, Milling head, Pneumatic Blade head, Marking pen, Punching, ect.

10

Application Pen Type

Common signing pen, Oil pen, Ball-point pen, Silver pen

11

Table Fixed Type

Vacuum worktable/Zoned adsorption platform

12

Rack and Linear Guide

Taiwan

13

Motor and Driver

Servo Type

14

Machine Base

Welded squre metal tube of heavy duty

15

Lubrication System

Automatic Lubrication

16

Control Software

Zhongrui

17

Support Files Format

PLT, AI, CDR, HPG, HPGL, ect.

18

Option Parts

CCD Camera, Big Camera, Projector, Automatic deviation correction loading rack

GET A QUOTE

Talk to Expert and Get Tailored Cutting Solution Free

Help you to cut smarter, faster, and better

FAQs

- Soft glass, sticker, thin plastic, billboard canvas, cardboard, foam board, acrylic board, PP hollow board, aluminum-plastic panel, honeycomb cardboard, soft film, card paper ect.

- Yes, it could cut printed cardboard directly without pre-setting a program file, thanks to the innovative CCD camera technology.

- MINI CCD camera could recognize printed materials with both drawings and markings, and is widely used in the advertising industry.

- The big camera can recognize printed materials without drawings or markings. The camera captures the image, converts it into a drawing, and then precisely cuts it.

- Absolutely! We can install multiple tools on one holder or independent holders installed.

- Yes, the consumables are blade and felt.

- We provide free installation and training online.

- Our engineer will help to install the machine at your factory if necessary.

- Regular cleaning and lubrication are essential, but most machines offer user-friendly maintenance routines. Some models even have automated cleaning mechanisms.

- The ROI varies depending on factors like production volume, labor costs, and material savings. However, many businesses see a significant return on investment within a short period due to increased efficiency and reduced waste.

- All machines are relatively user-friendly and require minimal training. We offer training resources and support to ensure smooth operation.

- 1 year of whole machine;

- Free technicial support and software updating of lifetime;

- Repair parts and consumables that need to be replaced are provided to customers at dealer prices.