A Complete Guide to 2100×3000 CNC Oscillating Knife Cutting Machines for PVC and Multi-Material Industrial Cutting

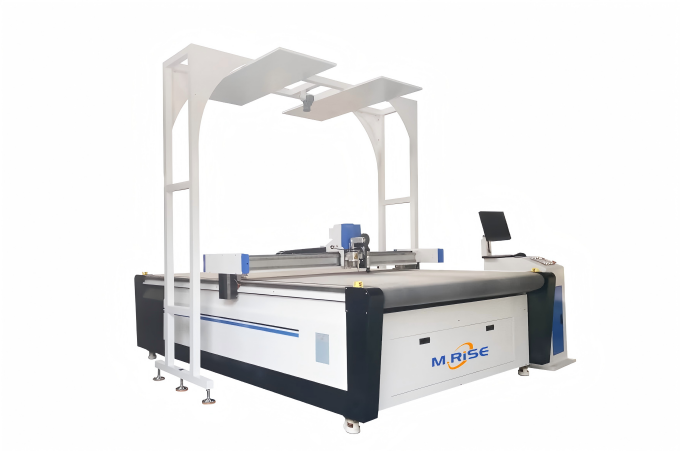

1. Introduction: Why Choose a Large-Format CNC Oscillating Knife Cutter?

As more manufacturers transition from manual cutting to automated digital cutting, demand for large-format CNC oscillating knife machines—such as 2100mm × 3000mm, 1800mm × 3000mm, and 2500mm × 6000mm—continues to rise.

Industries such as PVC industrial doors, tarpaulin fabrication, signage, packaging, footwear, foam processing, and composite material cutting are increasingly looking for:

- Higher accuracy

- Faster production cycles

- Zero-burn, zero-smoke cold cutting

- Automated tool switching

- Compatibility with diverse materials

For applications like cutting 2mm PVC, a CNC oscillating knife system is one of the most efficient and safest solutions—far superior to hot cutting or laser cutting, which can burn PVC and release harmful fumes.

2. Machine Models and Working Sizes

To meet different material widths and production scales, we provide multiple working area options:

- Model MR-1625: 1600*2500mm;

- Model MR-2130: 2100*3000mm;

- Model MR-2060: 2000*6000mm;

- Model MR-3080: 3000*8000mm

These platforms are suitable for PVC sheets, tarpaulin, corrugated cardboard, KT board, foam, adhesive stickers, grey board, and even soft automotive materials.

3. Industrial-Grade Mechanical Structure

To ensure stable and precise cutting over long-term operation, the machine adopts:

- Overall precision-welded body

- High-strength aviation aluminum gantry

- Precision rack + linear guide transmission

- AC servo motor drive system

This structure maintains 0.01mm repeatability and 0.02mm mechanical precision, delivering consistent results even in 24/7 production environments.

4. Cutting Tools: Multi-Function & Flexible

Our CNC cutting head supports a wide range of industrial-grade tools:

- Standard & Optional Tools

- Oscillating Knife (EOT)

- Rotary Cutting Knife

- Pneumatic Knife

- Drag Knife

- V-Cut Knife

- 45-Degree Beveling Knife

- Creasing Wheel

- Kiss-Cut Knife

- Punching Knife

This tool ecosystem makes the machine capable of cutting:

- PVC sheets & films

- Tarpaulin

- Corrugated cardboard

- Thick EVA foam

- KT board

- Carpet

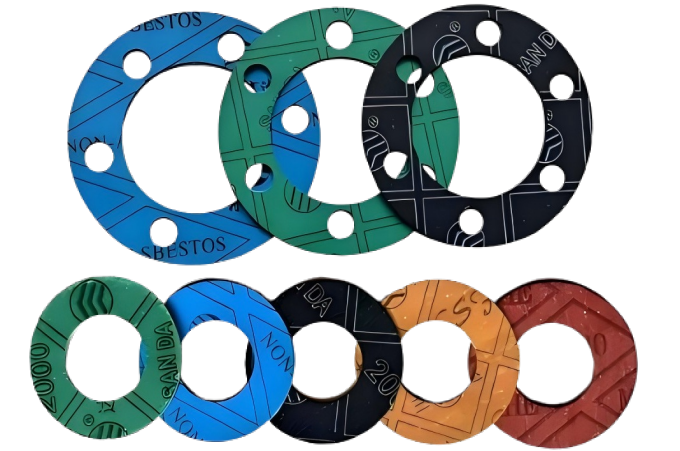

- Rubber gaskets

- Automotive interior fabrics

- Adhesive vinyl stickers

It truly functions as a multi-material cutting platform.

5. Vacuum Table & Material Fixing System

To hold thin or flexible materials firmly, the machine uses:

- Aviation-aluminum vacuum adsorption platform

- High-power vortex vacuum pump (5.5kW / 7.5kW / 9kW optional)

- Intelligent zone vacuum control

This guarantees stable cutting, especially for:

- PVC film

- 1–3mm PVC expansion sheets

- Tarpaulin

- Foam sheets

- Thin plastic and rubber

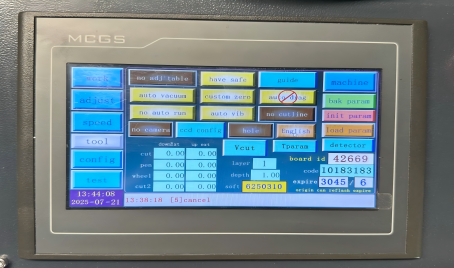

6. CNC Control System & Software

We support advanced CNC platforms including:

- Ruida RDC/Zhongrui control system

- Kinco control system

- HPGL compatible instruction format

- USB / Ethernet data transmission

- 4GB buffer capacity

- Chinese & English touch screen

Users can import DXF, AI, PLT, DWG, PDF files directly.

Software is beginner friendly, suitable for operators without CNC experience.

7. Cutting Performance for PVC (Especially 2mm PVC)

- Maximum Cutting Speed: 0–1500mm/s (material dependent), Up to 2000mm/s on light materials

- Edge Quality: Smooth, burr-free; Zero burning (because it’s cold cutting); No toxic smoke

- Accuracy: Repeat accuracy: 0.01mm; Mechanical precision: 0.02mm

- Applications: PVC industrial doors; Soft film doors; Tarpaulin & tent fabric; Signage materials; PVC expansion board; Gasket cutting

The machine is engineered for daily mass production.

8. Vision Positioning System (Optional)

For printed materials:

- Camera recognition

- Projection positioning

- Automatic contour detection

This is ideal for:

- Printed PVC banners

- Advertising boards

- Label & sticker die-cutting

- Automotive interior patterns

9. Electrical Specifications & Safety

- Operating voltage: AC 220V / 380V 50–60Hz

- Rated power: up to 12kW (depending on configuration)

- Safety system: Infrared sensor; Emergency stop switches; High-sensitivity interaction protection

- Engineered for global industrial parks and high-demand manufacturing lines.

10. Price, Availability & Lead Time

Direct factory price from Jinan M.RISE Machinery:

- Price range: USD $8,500 – $14,000(Depending on size, tool setup, and vision system)

- Production lead time: 7–12 working days

- Warranty: 3 years

- Support: Lifetime free technical support

- Worldwide shipping available.

11. Why Global Customers Choose Our Factory

- 10+ years digital cutting machine manufacturing

- Exported to 70+ countries

- CE / FDA / ISO9001 certified

- 300+ units annual production

- Deep expertise in PVC cutting, tarpaulin cutting, gasket cutting

- Powerful after-sales + online training + remote diagnostics

- From industrial doors to packaging, our machines deliver stable, reliable, and precise cutting performance.

12. Frequently Asked Questions (FAQ)

- Q1: Will the knife get stuck when cutting PVC?

- No. The oscillating knife is designed for flexible plastics up to 5mm.

- Q2: Do I need air pressure?

- For standard oscillating knife: not required.

- For pneumatic knife: 6 bar air pressure.

- Q3: Can it cut printed PVC?

- Yes, with a camera + contour recognition system.

- Q4: How long does the blade last?

- Typically 2–8 weeks depending on usage.

- Q5: Is the software easy to learn?

- Very easy—simple interface, supports English.